Author: Dave Williams; dlwilliams=aristotle=net

My Stewart-Warner Model 2000 balancing machine after I got it unloaded in the

shop. I bought it in Clarksville, Tennessee. It had been used in an electric

motor shop so there were no accessories for balancing engines, and humidity

had gotten to some of its circuitry. I sent the electronics back to Stewart-

Warner for (expensive) overhaul, then built their recommended fixtures to

recalibrate the machine on site. The SW engineer said they'd never had anyone

do that before... The sucker weighs about 900 pounds according to the service

manual.

My Stewart-Warner Model 2000 balancing machine after I got it unloaded in the

shop. I bought it in Clarksville, Tennessee. It had been used in an electric

motor shop so there were no accessories for balancing engines, and humidity

had gotten to some of its circuitry. I sent the electronics back to Stewart-

Warner for (expensive) overhaul, then built their recommended fixtures to

recalibrate the machine on site. The SW engineer said they'd never had anyone

do that before... The sucker weighs about 900 pounds according to the service

manual.

This is a replacement roller setup. Ford cranks have the oil hole in just the

wrong place. If even the edge of the hole contacts the roller it overwhelms

the balance signal, and on the Fords, the hole is in just about the same place

as the usual heavy spot, so you have no idea what's going on. I made the

fixture using narrow ball bearings to ride to the side of the oil hole. I

don't see how anyone can balance a small block Ford with the stock pieces;

maybe they don't even try.

This is a replacement roller setup. Ford cranks have the oil hole in just the

wrong place. If even the edge of the hole contacts the roller it overwhelms

the balance signal, and on the Fords, the hole is in just about the same place

as the usual heavy spot, so you have no idea what's going on. I made the

fixture using narrow ball bearings to ride to the side of the oil hole. I

don't see how anyone can balance a small block Ford with the stock pieces;

maybe they don't even try.

$50 worth of aluminum bar stock sawed up and partially machined. The holes

are to hold brass weights.

$50 worth of aluminum bar stock sawed up and partially machined. The holes

are to hold brass weights.

I had to make a 45 degree V block adaptor for the mill vise before I could

mill the vees in the weight clamps. The finished clamps came out within one

gram of each other. Not bad eh?

I had to make a 45 degree V block adaptor for the mill vise before I could

mill the vees in the weight clamps. The finished clamps came out within one

gram of each other. Not bad eh?

The first of several pieces of brass bar stock, totaling almost $100. A light

cut first to ensure a consistent OD.

The first of several pieces of brass bar stock, totaling almost $100. A light

cut first to ensure a consistent OD.

Setting up a weight set. Two clamps, brass weights, and stainless steel

washers. Digital scale came from Office Depot, half the price of the same

scale from the machine tool vendors. Bench surface is a plastic 18-wheeler

mud flap.

Setting up a weight set. Two clamps, brass weights, and stainless steel

washers. Digital scale came from Office Depot, half the price of the same

scale from the machine tool vendors. Bench surface is a plastic 18-wheeler

mud flap.

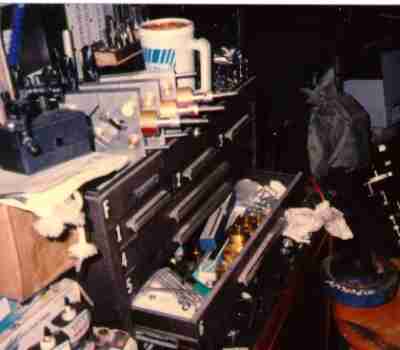

Balance weights and bits. I had to make a lot of stuff. A commercially made

set goes for about $1200 though, so I did okay.

Balance weights and bits. I had to make a lot of stuff. A commercially made

set goes for about $1200 though, so I did okay.