ScottB's 383W

This page: www.bacomatic.org/~dw/scottb/scottb.htm

Main page: http://www.bacomatic.org/~dw/index.htm

Last Updated: 16 Jul 2003

Author: Dave Williams; dlwilliams=aristotle=net

Some assembly photos of Scott Bronson's 383 Windsor. Most of them came out

sort of glary; what the heck, I'm not a photographer.

Cut and uncut pistons. They are Diamond Racing forged, domed Chevy pistons

with the domes hand-profiled for Ford combustion chambers. They were PolyDyn

coated when they arrived. Scott got them used at a very good price, but the

domes had to go to keep the 383 out of Diesel territory.

Milling one of pistons. I'm also reducing the pin height slightly to keep

them from sticking out the top of the block. Getting compression is *not* a

problem with a stroker! Note lightweight wristpin visible in upper left

corner. The pins were somewhat worn. We had two options; either replace them

or try coating them. Scott was amenable to being a guinea pig, so after

extensive discussion with the owner of Tech Line the pins were prepped,

coated, and polished down to the correct size. Tech Line says they used to do

that for the Nissan factory IMSA cars.

Chevy 6.2" Eagle rods have just been narrowed for the Ford journals. Scott

got them along with the pistons. Next step is to resize the big ends. I'm

doing several sets of Chrysler rods for 375 Windsors at the same time. The

lathe is a 16" South Bend, made somewhere around a hundred years ago. I'd

just acquired it a few days before this photo was taken.

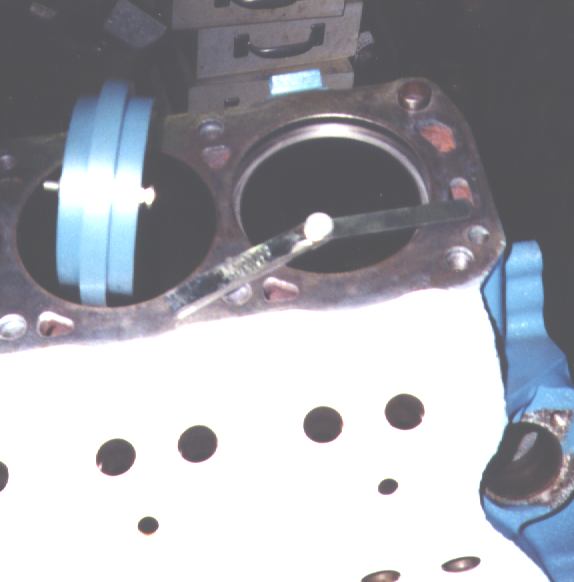

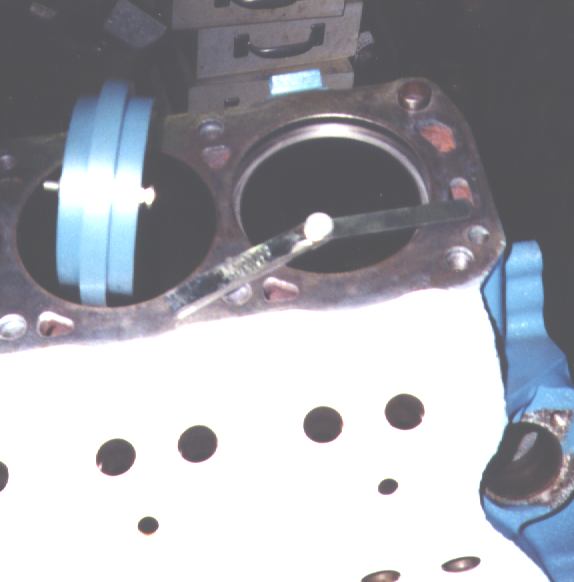

Checking ring gaps. Expensive Speed-Pro file-fit rings take a lot of grinding

before they fit. I clamp my Dremel tool in one of the bench vises and use the

side of a fiber cut-off wheel. Spiffy PVC plastic ring tool pushes ring down

straight in bore; double sided for 4.00 and 4.125" bore sizes.

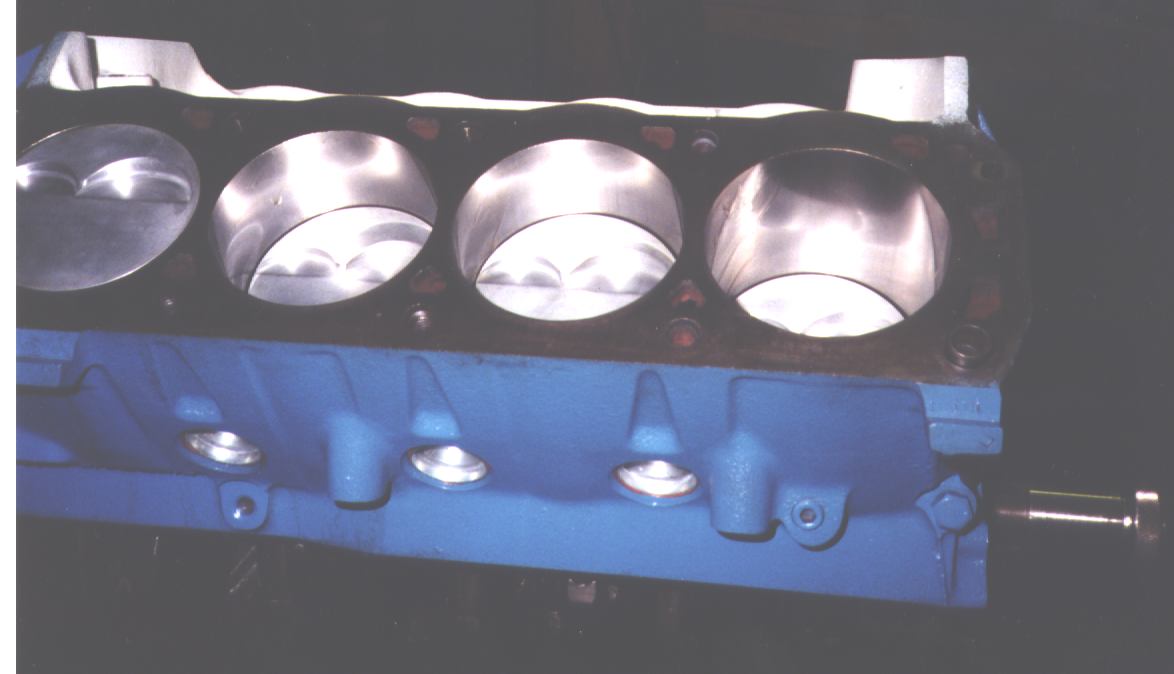

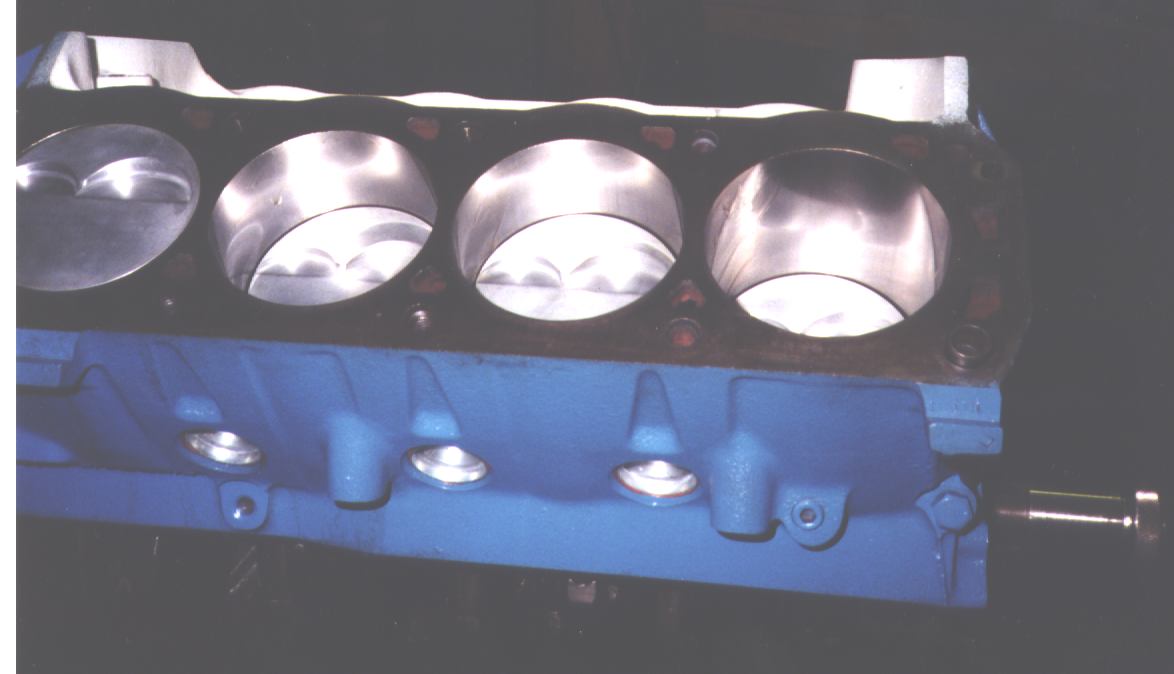

First piston/rod assembly goes in. Deck height is zero.

All pistons in. They've been recoated with Tech Line CBC2 ceramic thermal

barrier on top and TLML antifriction moly on the sides. Note the very smooth

cylinder wall finish.

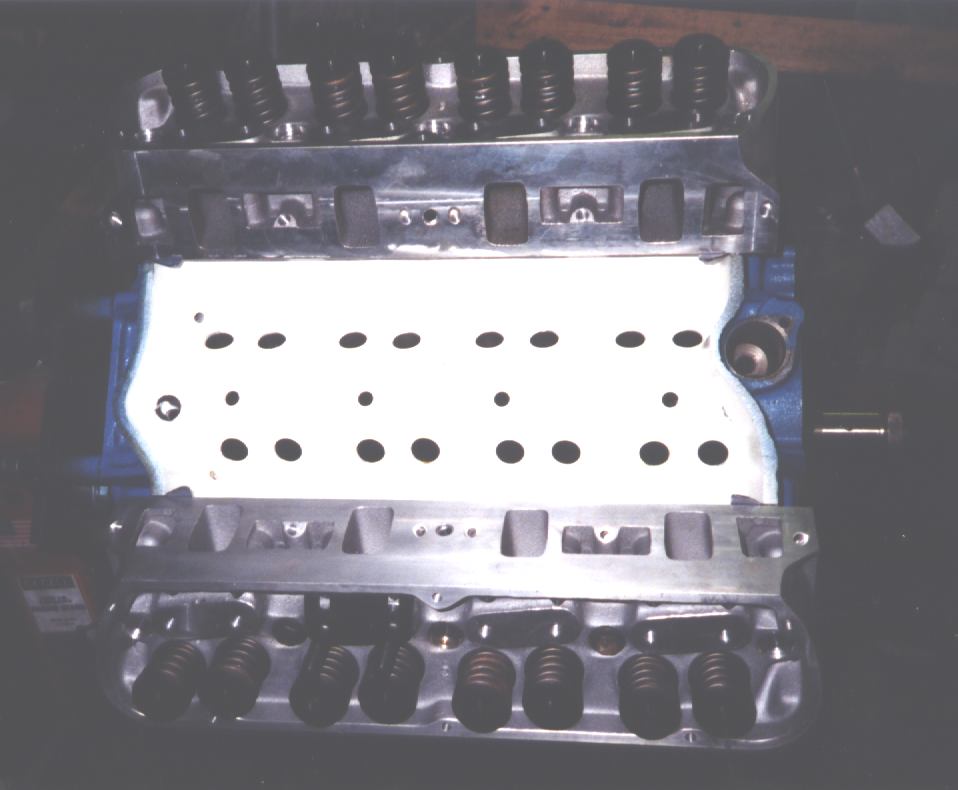

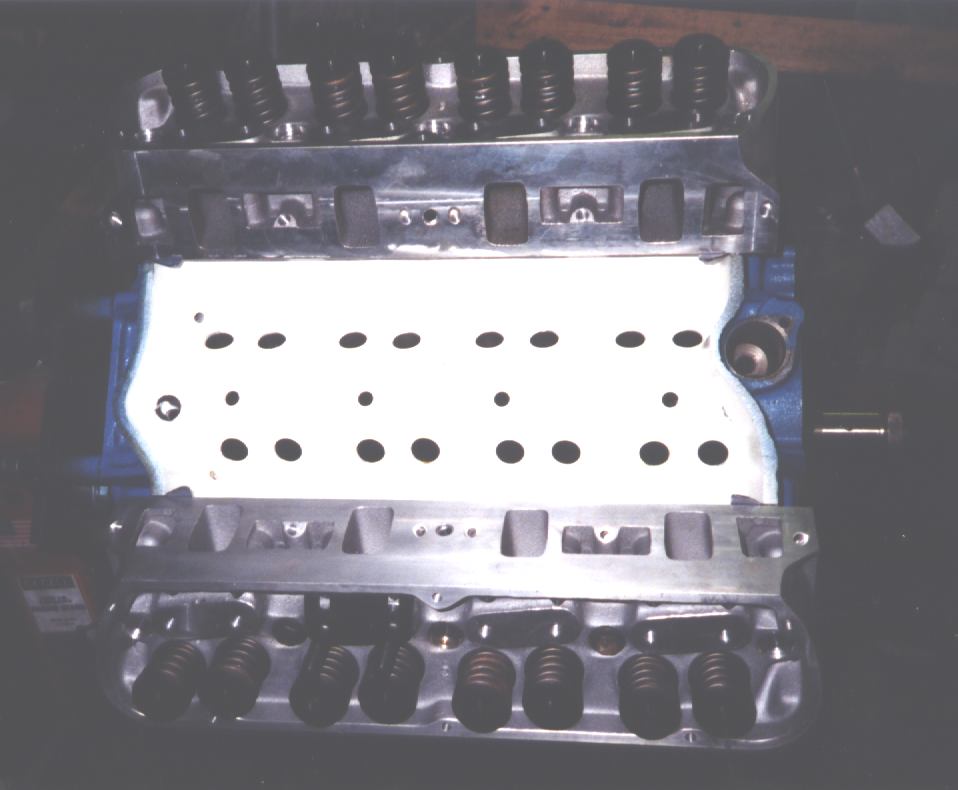

Shot from above with the heads in place. Nice color scheme eh?

Installing the cam. I'm using a 24" round aluminum bar with a 3/8-16 stud in

one end. No leverage problems here!

This is a couple of weeks later; it took time to special order the pushrods.

It wound up with half a set one length, half a set the other. The combination

of Wedgies and different rocker ratios on the intake and exhaust made the

required pushrod length dramatically different. The "twisted" trait of the

Twisted Wedge heads is very visible in this shot.

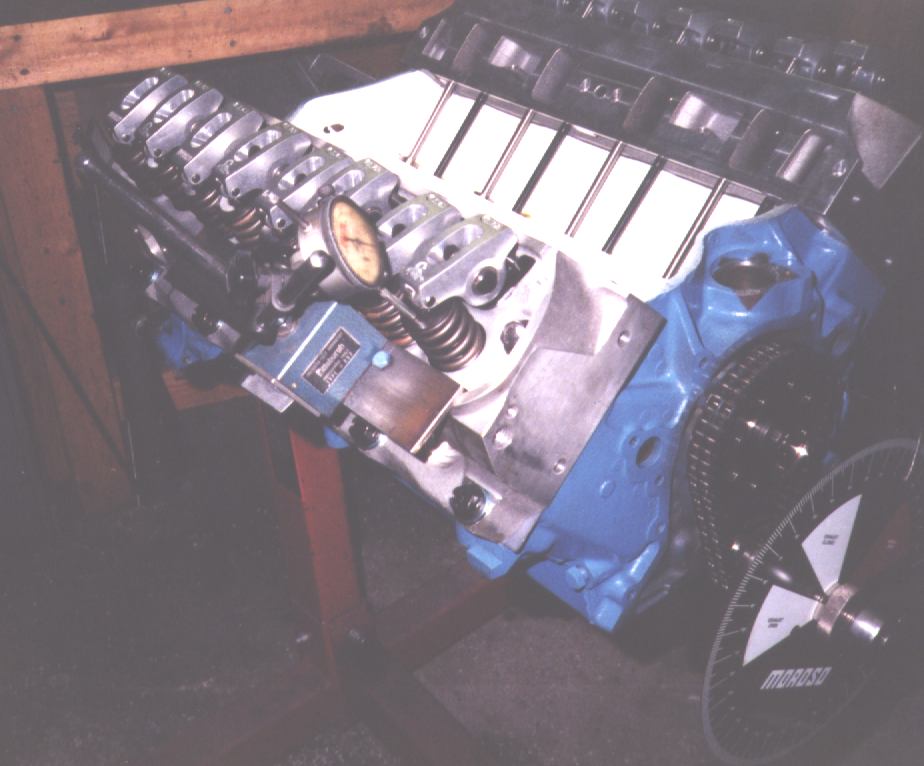

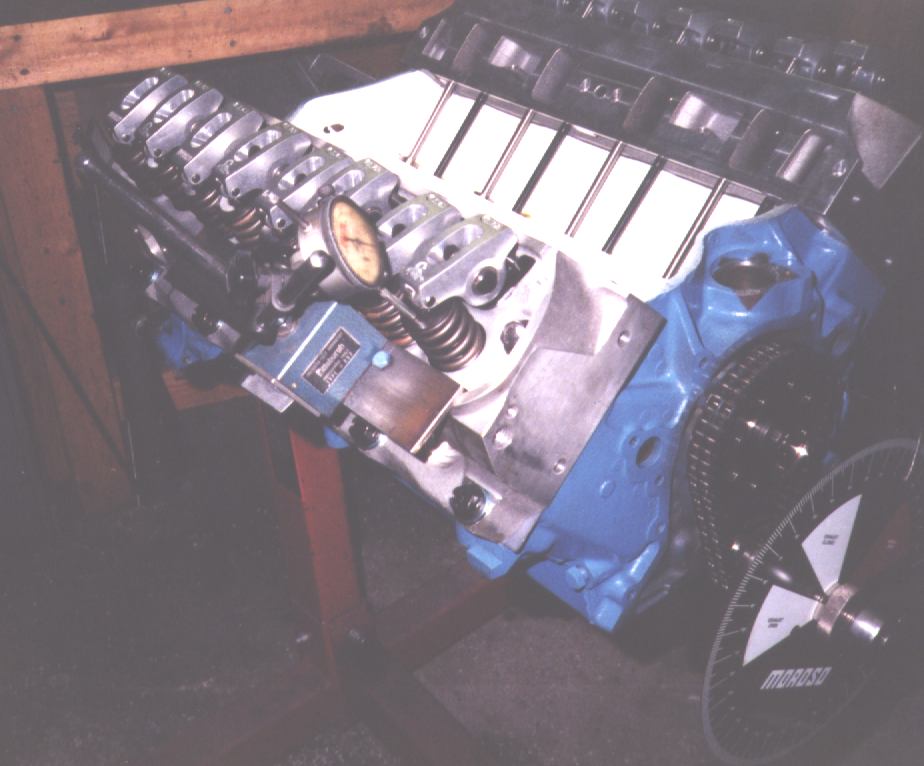

Degreeing in the cam. I wound up having to make a steel plate to bolt to the

valve cover rail to degree the cam in. One more tool for the arsenal...

===========================================================================

383 Ford Stroker

completed 02/19/99 for Scott Bronson, Santa Clara, California

351W Ford stroked to 3.70", .060 overbore (383 CID)

Competition Cams 222/[email protected], .496/.496 hydraulic cam

TFS Twisted Wedge heads

Compression:

785cc swept volume (bore/stroke 4.060/3.70)

61 cc nominal chamber volume

2.1cc -.010 assembled height

7.3cc .035 gasket

5 cc valve trough (estimated)

--------

75.4cc total clearance volume

785 / 75.4 = 10.4:1 CR

COMPONENTS ---------------------------------------------------------------

crankshaft:

early style 351W casting

stroked to 3.700

mains 351W -.020

rods Chrysler 360 standard (2.123")

balanced 28oz (drill only)

pistons:

TRW/Diamond forged for 350 Chevy

machined to flat top with two valve reliefs, 1.43 pin height

4.060 diameter

CBC2 ceramic coated tops

Polydyn moly coated underside

TLML coated sides

TLML coated pins

rings:

standard small block Chevy. 4.060, file fit, Speed Pro moly top

side clearance .003 top and second

ring gaps .011 second, .013 top (Ford spec .010-.020) .016 oil

1/16, 1/16, 3/16"

rods:

Eagle 6.20" Chevrolet

narrowed big ends (.835)

bearings large journal Chevy (2.1") narrowed, TLMB coated

rod side clearances .010

resized big ends (minimum size)

chamfered sides of big ends

bronze bushed for floating pins

block:

1971 351W D1 casting

bored .060

honed to .045 piston/wall clearance, spec for TRW forging

honed to #600 finish (ultra smooth)

2 piece rear main seal (blue silicone around edges)

new core plugs (blue silicone sealer)

painted (Rust-Oleum Sail Blue)

new cam bearings (King)

heads:

TFS Twisted Wedge (customer's heads)

pushrods:

8.25" exhaust (TFS customs)

8.20" intake (Ford Motorsport 351W)

rockers:

Scorpion 1.6 roller intake (customer provided)

Scorpion 1.72 roller exhaust

timing set:

Rollmaster full roller, 9-way keyway (customer provided)

cam:

PART # 35-000-5

ENGINE FORD 351 WINDSOR

GRIND NUMBER FW268-4-276-4H112

SERIAL NO D 7889

VALVE ADJUSTMENT HYD HYD

GROSS VALVE LIFT .494 .494

DURATION AT

.006 TAPPET LIFT 268 276

VALVE TIMING OPEN CLOSE

AT .050 INT 1-BTDC 43 ABDC

EXH 45 BBDC 1 ATDC

THESE SPECS ARE FOR CAM INSTALLED

AT 112 INTAKE CENTER LINE

INTAKE EXHAUST

DURATION AT .050 222 226

LOBE LIFT .3090 .3090

LOBE SEPARATION 112

degreed in at 112 intake centerline

flywheel:

Motorsport casting, originally 50oz, match balanced to 28oz

===========================================================================

Stewart-Warner Model 2000 Industrial Balancer

balance:

balanced for 28oz damper and flywheel

Eagle rods, narrowed:

214g pin end

504g big end

574g TRW-Diamond .060 forgings, 1.43 pin, lightweight pins tops milled flat

46g std SBC LJ rod bearing

44g .020 narrowed rod bearing

3g retainers

50g thin rings, .060 over

546g pistons/pins

50g rings

3g locks

218g small end of rod

---

857g

857/2 = 428g reciprocating

501g big end of rod

+ 44g rod bearing, narrowed

---

545g rotating

428g

+545g

---

973g bob per cylinder

x2

---

1946g per journal

setup RPM 800

balance RPM 650

residual imbalance .04 front, .03 rear

(balance is 1/10 of standard spec; close to the machine's resolution limit)

===========================================================================

Return to Dave's home page