My brother Kevin is the current custodian of the family's '65 Chevy pickup. It's the heavy duty 3/4 ton long wheelbase model, with steel door panels, steel headliner, and a rubber mat on the floor - just hose it out. Two barrel 283, granny-low four speed, and a 4.56 Detroit Locker in the back. Our Dad bought it in 1970. Since then it's carried a cabover camper, then a camper shell, hauled concrete blocks, wet sand, trailers, and even a small mobile home.

After 35 years the 283 was getting a little tired. Kevin decided a whole new motor would be the way to go. The 283 actually had adequate power, even in its senior citizen years. Kevin considered building a fresh 283, or maybe moving to a 305. I had the basic parts on hand to do a 307. Dave's Law: "Cheap Is A Quality Overcoming Many Faults."

The 307 can be considered an underbored 327 or a stroked 283. It's an eighth of an inch more bore than a 305 and a quarter inch shorter stroke. By rights they should run pretty good - better than a 305 - but production 307s were all low compression, wimpy cam timing, generally low performance motors. Kevin's 307 is none of the above.

Disassembling an old set of lifters to use as plugs for the lifter bores. I'm

partial to spraying white epoxy paint in the lifter valley. I could claim it

enhances oil drainback or something, but in truth, I just like the way it

looks. I have some nice plastic plugs I use for Ford motors, but the Chevy's

smaller diameter lifters required some fangling.

Disassembling an old set of lifters to use as plugs for the lifter bores. I'm

partial to spraying white epoxy paint in the lifter valley. I could claim it

enhances oil drainback or something, but in truth, I just like the way it

looks. I have some nice plastic plugs I use for Ford motors, but the Chevy's

smaller diameter lifters required some fangling.

A bit of tape wrapped around the end of the lifter keeps it from falling

through. The block came out of the hot tank, was pressure washed, and then

thoroughly scrubbed with Tide and a bristle brush before being dried with

compressed air. It's trying to rust even as I'm shooting the picture. The

cleaner the metal is, the better the paint sticks.

A bit of tape wrapped around the end of the lifter keeps it from falling

through. The block came out of the hot tank, was pressure washed, and then

thoroughly scrubbed with Tide and a bristle brush before being dried with

compressed air. It's trying to rust even as I'm shooting the picture. The

cleaner the metal is, the better the paint sticks.

Just came out of the honing tank. Now I get to run a tap in every single

threaded hole to make sure the threads are clean...

Just came out of the honing tank. Now I get to run a tap in every single

threaded hole to make sure the threads are clean...

Cleaning the cylinder bores. I'm using Marvel Mystery Oil, which is just a

decent grade of 5-weight oil, but ordinary automatic transmission fluid works

just as well. The oil floats honing grit out of the cylinders where it can be

picked up by a paper towel. The cylinders are honed to a #400 finish, which

is pretty darned smooth. Even so, the first few passes of the paper towel

come out silver with metal. You keep oiling and wiping until the towels come

out clean. No, most shops *don't* do this; it's a pain in the ass, and time

is money.

Cleaning the cylinder bores. I'm using Marvel Mystery Oil, which is just a

decent grade of 5-weight oil, but ordinary automatic transmission fluid works

just as well. The oil floats honing grit out of the cylinders where it can be

picked up by a paper towel. The cylinders are honed to a #400 finish, which

is pretty darned smooth. Even so, the first few passes of the paper towel

come out silver with metal. You keep oiling and wiping until the towels come

out clean. No, most shops *don't* do this; it's a pain in the ass, and time

is money.

The 307 crank coming out of the hot caustic cleaning tank. I use a chain

hoist because straight-arming a 50 pound crank (at 180 Fahrenheit and covered

with caustic cleaner) is no fun. This is an ordinary cast crank, large

journal.

The 307 crank coming out of the hot caustic cleaning tank. I use a chain

hoist because straight-arming a 50 pound crank (at 180 Fahrenheit and covered

with caustic cleaner) is no fun. This is an ordinary cast crank, large

journal.

This particular crank had been damaged on the first rod throw.

Someone's backyard overhaul didn't include tightening the rod nuts, and one

cap had come off and the bolt had gouged the oil hole in the rod throw. I

dismembered an old 'D' cell flashlight battery, carved the carbon rod with a

pocket knife until it fit in the mangled oil hole, preheated the crank with a

large propane torch, and MIG-welded the damaged section. Then I tapped the

carbon plug out from the other end of the oil gallery; no need to drill

through a weld.

This particular crank had been damaged on the first rod throw.

Someone's backyard overhaul didn't include tightening the rod nuts, and one

cap had come off and the bolt had gouged the oil hole in the rod throw. I

dismembered an old 'D' cell flashlight battery, carved the carbon rod with a

pocket knife until it fit in the mangled oil hole, preheated the crank with a

large propane torch, and MIG-welded the damaged section. Then I tapped the

carbon plug out from the other end of the oil gallery; no need to drill

through a weld.

Now the crank is cosmetically pretty after being turned 10/10. You can

see where the metal is a slightly different color after the crank was

reground, but it's on-size. I don't have an "after" picture to show you.

Rod and main bearings. They've been coated with Tech Line's TLML moly coat.

This is right after they've been sprayed; they get baked for several hours,

then polished afterward.

Rod and main bearings. They've been coated with Tech Line's TLML moly coat.

This is right after they've been sprayed; they get baked for several hours,

then polished afterward.

Putting the cup plugs in the front oil galleries. A special cup plug driver

is looking at you head-on; it's the round silver thing at the cap end of the

Loctite tube. Swab the holes out with acetone, wipe the plugs with acetone,

dab them with Loctite, drive the plugs in, then stake the holes with a large

chisel - notice the marks. Not that I'm paranoid or anything...

Putting the cup plugs in the front oil galleries. A special cup plug driver

is looking at you head-on; it's the round silver thing at the cap end of the

Loctite tube. Swab the holes out with acetone, wipe the plugs with acetone,

dab them with Loctite, drive the plugs in, then stake the holes with a large

chisel - notice the marks. Not that I'm paranoid or anything...

The back plugs screw in. Getting the old ones out required an oxyacetylene

torch, a BFH, and for one particularly stubborn plug, a drill and a 1/4 NPT

tap to repair the threads. I'm installing new plugs with Teflon tape. The

next guy who needs to remove the plugs will be able to just unscrew them with

an Allen wrench.

The back plugs screw in. Getting the old ones out required an oxyacetylene

torch, a BFH, and for one particularly stubborn plug, a drill and a 1/4 NPT

tap to repair the threads. I'm installing new plugs with Teflon tape. The

next guy who needs to remove the plugs will be able to just unscrew them with

an Allen wrench.

Removing the old cam sprocket from the crank. It doesn't matter when you do

this step, but it's easiest when the crank is supported in a block. The strip

of wood on the right keeps the crank from turning.

Removing the old cam sprocket from the crank. It doesn't matter when you do

this step, but it's easiest when the crank is supported in a block. The strip

of wood on the right keeps the crank from turning.

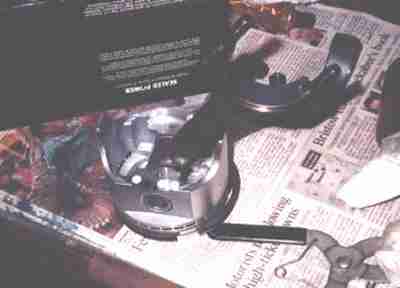

The pistons and rods have been assembled, the rings are installed, and the rod

bearing just went in. Now it gets two stroke oil on the rings, Mobil 1

synthetic oil on the wristpin and the skirts, and a special bearing lube on

the bearing and the sides of the rod where it rubs the crank cheek and the

other rod. A special lubricant for every occasion... lots of people use plain

old motor oil for everything, which works okay too.

The pistons and rods have been assembled, the rings are installed, and the rod

bearing just went in. Now it gets two stroke oil on the rings, Mobil 1

synthetic oil on the wristpin and the skirts, and a special bearing lube on

the bearing and the sides of the rod where it rubs the crank cheek and the

other rod. A special lubricant for every occasion... lots of people use plain

old motor oil for everything, which works okay too.

Here's an installed piston at bottom dead center. Notice the smooth cylinder

wall finish. Speed Pro, who made the rings, calls for a very smooth finish

for moly rings. Yes, they'll seat just fine. The days of crosshatched

cylinder walls went away with chrome rings. Notice these are flat top pistons

instead of regular 307 dish tops. With the 305 heads we'll be getting over

9:1 CR.

Here's an installed piston at bottom dead center. Notice the smooth cylinder

wall finish. Speed Pro, who made the rings, calls for a very smooth finish

for moly rings. Yes, they'll seat just fine. The days of crosshatched

cylinder walls went away with chrome rings. Notice these are flat top pistons

instead of regular 307 dish tops. With the 305 heads we'll be getting over

9:1 CR.

I'm fitting the crank scraper here. They're a sort of universal fit for a

350, but it still required trimming for a 307. Fortunately a Dremel tool made

it a short job. The scraper gets glued to the block with silicone sealer and

the oil pan gasket goes over it. Also in view are the Milodon oil pump

stud, Teflon tape on the water drain plug, brass freeze plugs, and my nifty

crank turning socket.

I'm fitting the crank scraper here. They're a sort of universal fit for a

350, but it still required trimming for a 307. Fortunately a Dremel tool made

it a short job. The scraper gets glued to the block with silicone sealer and

the oil pan gasket goes over it. Also in view are the Milodon oil pump

stud, Teflon tape on the water drain plug, brass freeze plugs, and my nifty

crank turning socket.

Now I'm fitting the Pete Jackson gear drive. The idler dogbone axles extend

back to hit the front of the block. They are made extra-long since the blocks

are just castings in front, and vary in their shape. I used a belt sander to

shorten the axles a little at a time.

Now I'm fitting the Pete Jackson gear drive. The idler dogbone axles extend

back to hit the front of the block. They are made extra-long since the blocks

are just castings in front, and vary in their shape. I used a belt sander to

shorten the axles a little at a time.

You install the dogbone with clay, tighten the timing chain cover (with a

gasket), disassemble, and measure the thickness of the clay. We're right in

spec.

You install the dogbone with clay, tighten the timing chain cover (with a

gasket), disassemble, and measure the thickness of the clay. We're right in

spec.

The inside of the timing chain cover, showing more checking clay. Grinder

marks are where the timing chain tab used to be welded on front; removing it

left holes that had to be welded shut.

The inside of the timing chain cover, showing more checking clay. Grinder

marks are where the timing chain tab used to be welded on front; removing it

left holes that had to be welded shut.

Here it is, all ready to go.

Here it is, all ready to go.

The steel strip welded in the cover provides a little extra support for the

camshaft thrust bumper. Nothing much holds a Chevy cam in place when it's

running - lifter thrust does some, but most of it is tension on the chain.

With gears instead of a chain, the cam has a tendency to walk forward. The

Pete Jackson gear drive came with a ball bearing thrust bumper.

The steel strip welded in the cover provides a little extra support for the

camshaft thrust bumper. Nothing much holds a Chevy cam in place when it's

running - lifter thrust does some, but most of it is tension on the chain.

With gears instead of a chain, the cam has a tendency to walk forward. The

Pete Jackson gear drive came with a ball bearing thrust bumper.

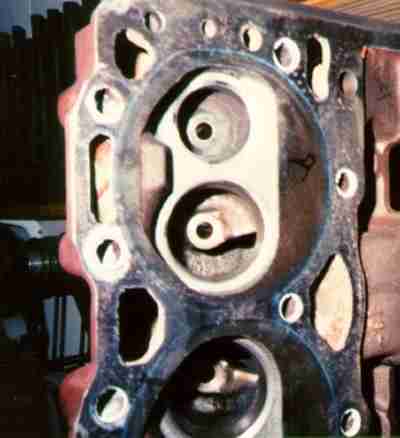

We topped the block with a pair of late model 305 heads. These are actually

350 heads, but they're very similar to the 305 heads. The intake port is very

tall and has a "corkscrew" vane that causes the incoming air to swirl.

Shooting water through the port with a garden hose makes a nice wide fan. The

swirl reduces emissions some, but its major benefit is fuel economy. For very

similar heads on the 4.3 V6, Chevrolet claimed figures on the order of an 8%

drop in power over 3000 RPM with a 12% increase in fuel economy and torque

across the entire useable powerband. This was a no-brainer for the 307; we

have power to burn compared to the 283, and the mileage and crisp throttle

response would be very nice. Note the sharp edge just below the intake valve

seat. This is a "fuel tripper" designed to re-introduce liquid fuel running

along the port floor into the airstream. According to David Vizard, who is

knowledgeable about such things, smoothing out the bowl area would give a

small increase in power with the penalty of a loss of fuel economy. We left

the fuel trippers alone for this particular application.

We topped the block with a pair of late model 305 heads. These are actually

350 heads, but they're very similar to the 305 heads. The intake port is very

tall and has a "corkscrew" vane that causes the incoming air to swirl.

Shooting water through the port with a garden hose makes a nice wide fan. The

swirl reduces emissions some, but its major benefit is fuel economy. For very

similar heads on the 4.3 V6, Chevrolet claimed figures on the order of an 8%

drop in power over 3000 RPM with a 12% increase in fuel economy and torque

across the entire useable powerband. This was a no-brainer for the 307; we

have power to burn compared to the 283, and the mileage and crisp throttle

response would be very nice. Note the sharp edge just below the intake valve

seat. This is a "fuel tripper" designed to re-introduce liquid fuel running

along the port floor into the airstream. According to David Vizard, who is

knowledgeable about such things, smoothing out the bowl area would give a

small increase in power with the penalty of a loss of fuel economy. We left

the fuel trippers alone for this particular application.

Here's another view of the intake port. Also notice the relocated spark plug,

up high and pushed closer to the center of the chamber. Kevin's heads have

had the valves unshrouded all the way to the cylinder walls, a fancy three

angle valve job, very minor porting on the exhaust side, and modified valves

with a 20 degree back-cut for better airflow. Plus they're cut for 7/16"

screw in studs and guide plates.

Here's another view of the intake port. Also notice the relocated spark plug,

up high and pushed closer to the center of the chamber. Kevin's heads have

had the valves unshrouded all the way to the cylinder walls, a fancy three

angle valve job, very minor porting on the exhaust side, and modified valves

with a 20 degree back-cut for better airflow. Plus they're cut for 7/16"

screw in studs and guide plates.

DISPLACEMENT -------------------------------------------------------------

3.905 bore (+.030)

3.250 stroke (+.250)

311 CID, 5103cc (5.1 L)

COMPONENTS ---------------------------------------------------------------

crankshaft:

Chevy 307, cast

mains -.010

rods -.010

balanced

bearings .010, Clevite 77

minor weld repairs on #1 and #2 throws

polished journals

pistons:

Sterling/Federal Mogul

cast 307 Chevy, .030 over

flat top with four reliefs

rings:

standard small block Chevy. 3.875 +.030, Speed-Pro

side clearance .003 top and second

ring gaps .011 top, .011 second, .015 oil

rods:

5.7" large journal

TLML moly coated bearings .010, Clevite 77

rod side clearances .012

resized big ends (minimum size)

block:

307, two bolt, two piece rear main

bored .030

honed to .003 piston/wall clearance

2 piece rear main seal (red silicone around edges)

new core plugs (red silicone sealer)

new cam bearings (Clevite 77)

all threaded holes chased

timing set:

Pete Jackson dual idler gear drive

cam installed at 4 advanced

cam:

Iskenderian hydraulic 270 Mega #201271

221/221 @.050, .465/.465 lift (w/1.5 rockers) .511/.511 (1.6) 108 LC

Rhoads variable-duration hydraulic lifters

oiling:

new Milodon high volume, high pressure pump

new Milodon oil pump pickup

Milodon crank wiper, trimmed to fit, glued in place with Ultra Copper

Milodon steel pump to drive rod bushing

stock Chevy oil pump drive rod

Milodon oil pump mounting stud

new Summit oil pan

intake:

Offenhauser Dual Port 360, Holley pattern

carburetor:

Carted 625 AFB, CFM

ignition:

Chevy HEI

heads:

187 casting, '90s 305 "corkscrew port" high swirl

late model re-angled center intake manifold bolts

for center-bolt valve covers

1.84/1.50 valves (original size)

45 degree valves and seats

new bronze guide liners

.001 valve/guide clearance

intake valve stem seals - shields, O-rings and umbrellas

exhaust valve stem seals - shields and O-rings

Competition Products #2350 valve springs, 120# @ 1.700, 300# @ 1.250

1.750 installed height

standard height intake keepers, -.050 exhaust keepers

bosses cut down and tapped for screw-in studs

ARP 134-7103 7/16" screw-in studs, torqued to 55 ft-lb with sealer

Crane 11650-1 stepped guide plates

Crane 11747-16 7/16", 1.6 ratio cast aluminum full roller rockers

surfaced flat on deck and intake face

Magnafluxed

valve seal vacuum checked

porting:

intake valves were back cut from the factory

ditch cut faces

exhaust valves 20 deg back cut, 45 deg chamfered on face

sides of combustion chambers opened up to 3.905" bore size, plunge

cut with seat grinding stones

side cuts rolled into front of chamber with die grinder, outer edge

extended to 3.905" bore size

intake valve pocket quench side rolled back with die grinder

intake and exhaust valve seats opened up to match OD of valve

60-45-30 degree three angle valve job

exhaust valve pockets cleaned up with die grinder

notes:

The intake ports were left alone, other than the larger diameter

seats. According to GM the sharp edges in the bowl are for fuel

shear, to reintroduce fuel droplets into the airstream. Most of the

work was done in the combustion chambers, unshrouding the valves as

per David Vizard's Chevrolet head porting book. The 187 heads have

the late model relocated spark plug, which is moved closer to the

center of the chamber and slightly to the exhaust side.

===========================================================================

Yep, that's a fairly large cam for a small motor. We never got around to

CC'ing the chambers, but I expect the compression ratio to be around 9.5:1.

The truck is turning around 3500 RPM at freeway speed; there was no reason to

build an RV-type lug-around motor; instead, we built the engine to perform

best at cruise speed.

At the time this was written, the 307 was wrapped up on Kevin's enclosed back

porch while he was upgrading the transmission and rear end. The 283 still has

some life in it, and there's no sense in putting the new engine in until the

rest of the driveline is fixed. The truck has a 4.56 Detroit Locker and a

Borg/Warner T-5 five speed now, and the next thing on the list is a new

exhaust system for the new shorty headers. The 283 doesn't show any signs of

impending doom yet...