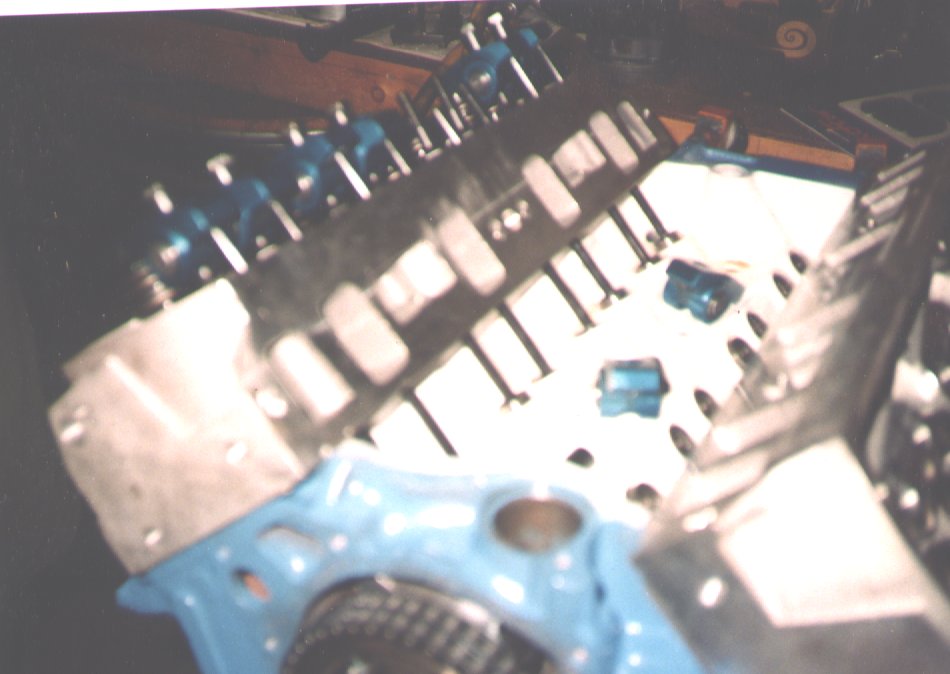

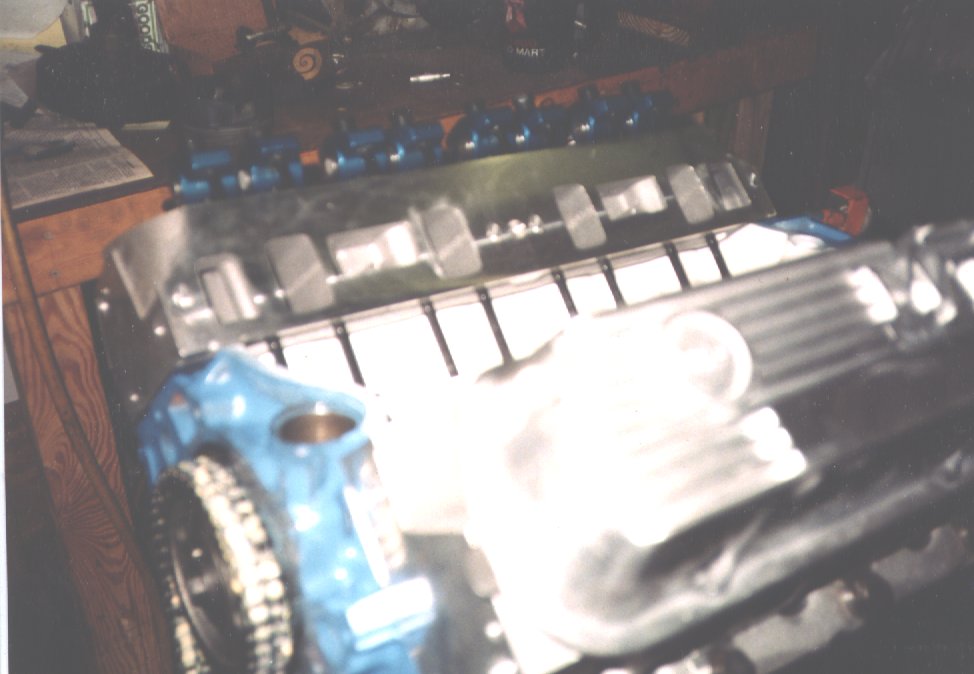

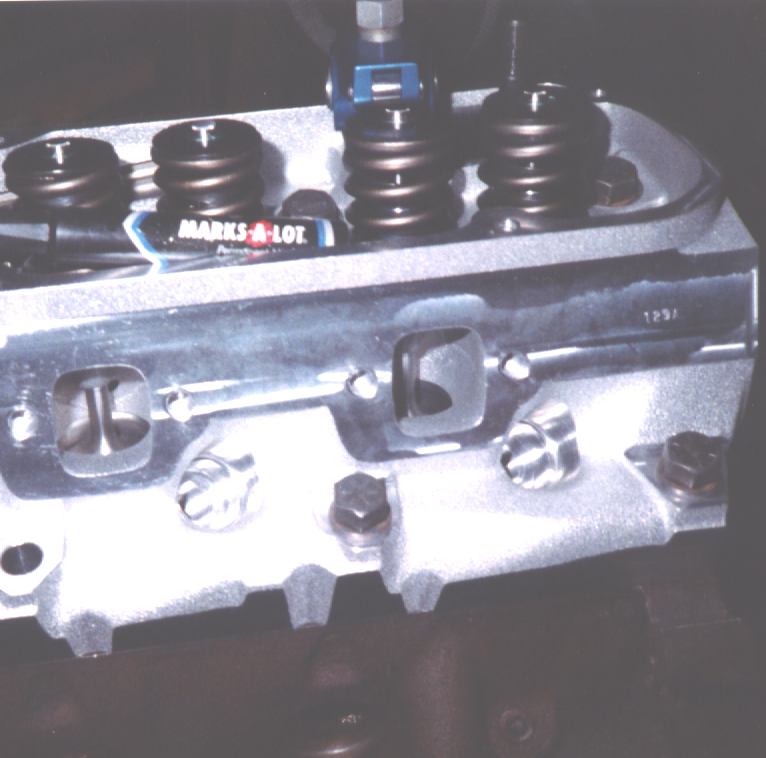

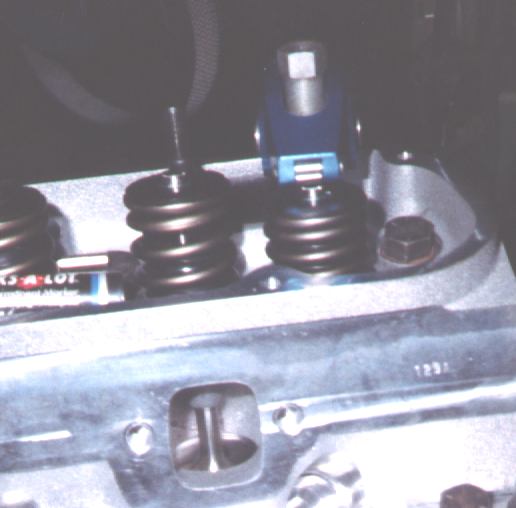

Just a few shots of the heads and lifter valley...

These are early Wedgies. They use special TFS pushrod guide plates, and that's how far they were off side-to-side. Very ungood. TFS shipped a set of revised guideplates when I called to ask what was going on.

With the new guide plates everything lined up fine. Magic Marker is for inking the ends of the valve stems to check pushrod length.

Kemper contemplating the Zen of cleaning valve covers. Kemper and his friend Lance came up from Vicksburg to pick the engine up, complete with the dead 302 in the back of Lance's truck. They pulled the pan, valve covers, intake, and assorted bits from the dead motor while I finished putting the 315 together, then spent the rest of the day cleaning dirty parts. They missed out on the black Jell-O, though...

===========================================================================

SPECIFICATIONS:

302 Ford stroked to .075", .030 overbore (315 CID)

Crane 222/234 @.050 hydraulic cam, rated 2200/5200 powerband, 6500 valve float

with 280# springs

(this cam turned out much lumpier than Kemper wanted. I'd built a previous

315 with a similar-duration cam that idled like a stocker, but that one had

a 112 degree lobe center. Kemper's is 108 degrees.)

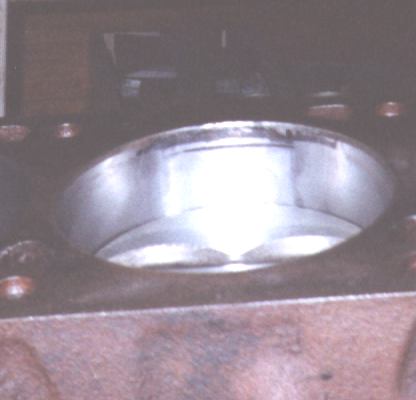

TFS Twisted Wedge heads, cut for Loc-Wire gaskets

Compression:

724cc swept volume (bore/stroke 4.030/3.075)

61 cc nominal chamber volume

5.2cc -.025 assembled height

7.3cc .035 gasket

5 cc valve trough (estimated)

--------

78.5cc total clearance volume

724/78.5 = 9.22:1 CR

===========================================================================

COMPONENTS ---------------------------------------------------------------

crankshaft:

302, 2M casting, full counterweight

stroked to 3.076"

mains 302 -.020

rods 2300 standard

polished journals

balanced (drill only)

pistons:

TRW forged 1.43 pin height (for 5.7 rod 383 Chevy stroker)

flat top with two valve reliefs

4.030 diameter

rings:

standard small block Chevy. 4.030, file fit, Speed Pro moly top

side clearance .003 top and second

ring gaps .011 second, .013 top (Ford spec .010-.020)

rods:

2300 Ford 5.205" D42E-AA forgings with oil squirt hole

narrowed big ends (.835)

pin ends opened to .925 (.002 press for .927 pins)

bearings 2300 Ford (narrowed .055 one side) (King)

rod side clearances .010

resized big ends (minimum size)

chamfered sides of big ends

oil holes in rods face cam

block:

1968 302 C8 casting

bored .030

honed to .005 piston/wall clearance, spec for TRW forging

honed to #600 finish (ultra smooth)

2 piece rear main seal (blue silicone around edges)

new core plugs (blue silicone sealer)

painted (Rust-Oleum Sail Blue)

#80 (.030) hole drilled in 1/2" cup plug behind distributor shaft

new cam bearings (King)

.040 hole drilled into oilway below distributor gear for oiling

heads:

TFS Twisted Wedge

cam:

Crane Powermax H-278-2, 222/234 @.050, .498/.527 lift, 110 LC

Crane cam lube used for assembly lube

firing order: 1-5-4-2-6-3-7-8

pushrods:

7.2" (checked) (stock 6.6")

rockers:

Ford SVO 1.6 roller

timing set:

double roller, Dynagear

oil pump:

Melling high volume, used, disassembled & cleaned

===========================================================================

Stewart-Warner Model 2000 Industrial Balancer

balance:

643 piston/pin

165 pin end of rod

55 rings

---

863 grams reciprocating

426 rod big end

34 rod bearing

---

460 rotating

bob = 1x reciprocating + 2x rotating

= 863 + 460*2

= 863 + 920

= 1784

+ 2 grams oil allowance

bob = 1786 grams

critical speed 800 RPM

resonant speed 650 RPM

max front imbalance .025 oz/in

max rear imbalance .045 oz/in

(balance is 1/10 of standard spec; close to the machine's resolution limit)

balanced for 28oz damper and flywheel

============================================================================