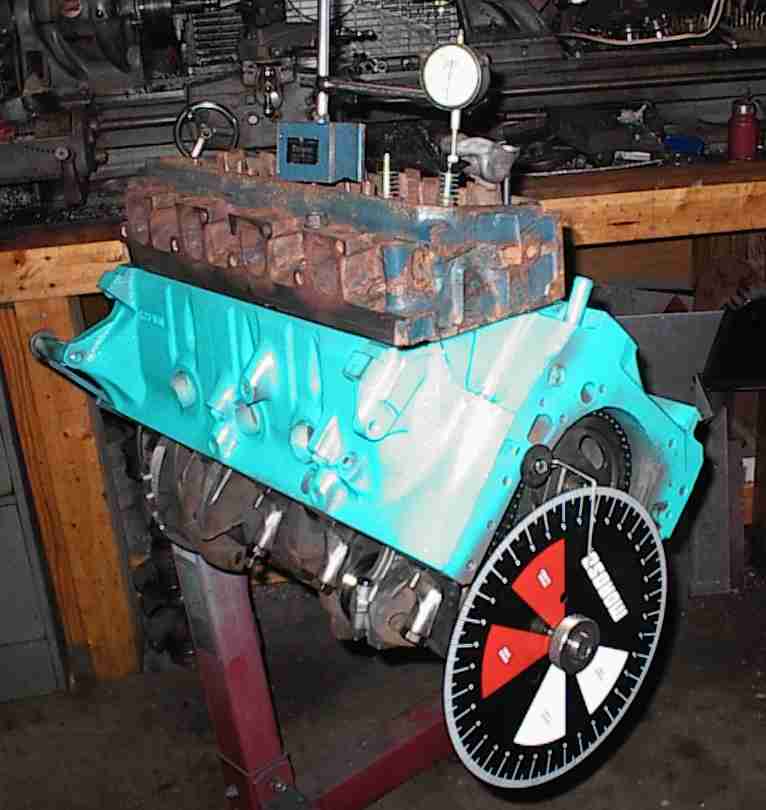

Checking valve-to-piston clearance. The pistons stick out of the bore .015".

Author: Dave Williams; dlwilliams=aristotle=net

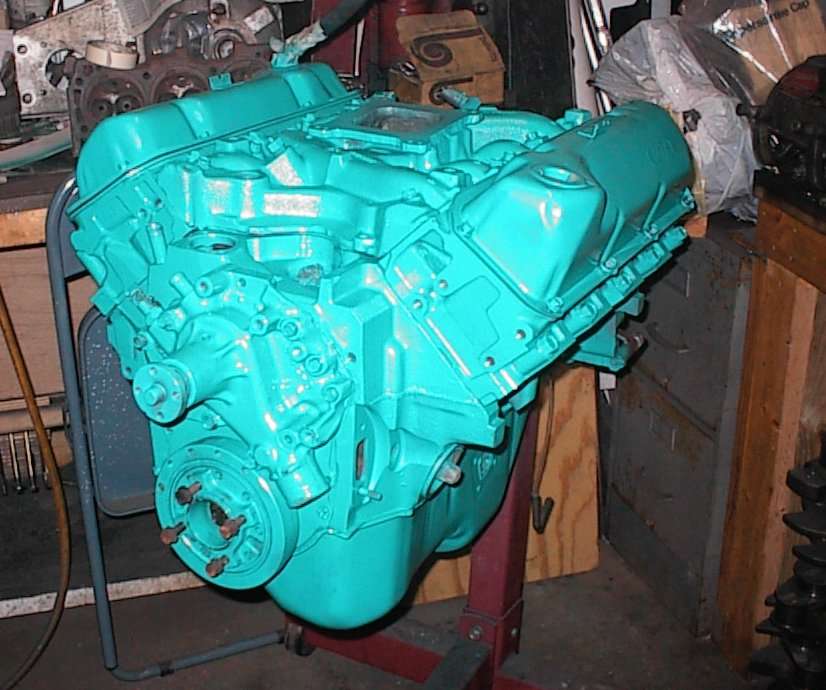

I trade some work with another engine builder and the balance of favors had fallen out of alignment a bit, so I put together a new engine for his shop truck. It had a 351M in it already, so the choice was clear... it had to be upgraded to a 400M and then opened up as much as practical.

I still have some pictures on 35mm I have to scan in, but these will show you most of it.

These are real, early-type 351C-2V heads. I didn't think to take any pictures of the differences, but though it's widely claimed (even by Ford!) that the 351M and 400 use 2V Cleveland heads, it's not true. The 2V head has a nice smooth exhaust port. The M head has a "potbelly" port you can barely get your finger through, with the water jacket drooped down around the valve guide. You can't grind the potbelly out because there's water inside it.

I went through what I thought was a stash of 2V heads and *all* of them were M

heads. I wound up giving all nine of them away. Kenney scrounged up two 2V

heads from two different core engines. They needed a lot of TLC after laying

out in the rain for several years, but they're a much better head than

the M heads.

Closest is right out of the caustic tank, middle is resurfaced to get rid of

the wear spot from the valve stem, farthest has been wire wheeled and run

through the parts tumbler.

MMO has a stupid name, but it's just a simple straight-cut, light base stock utility oil, like 3-in-1, except in big cans.

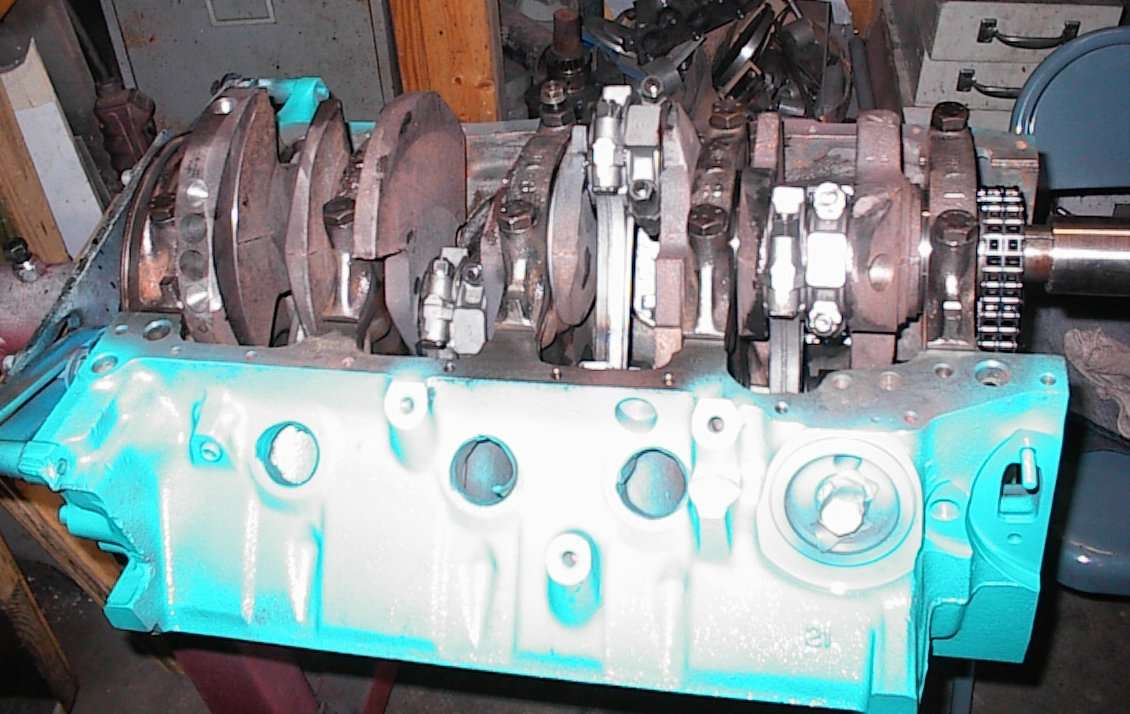

Notice the ugly appearance of the lifter valley. It's smooth enough, but the

blotchy effect is from dirty casting sand and/or the iron being a little too

hot when it was poured. Not that it means anything in particular; I just

thought you might be interested.

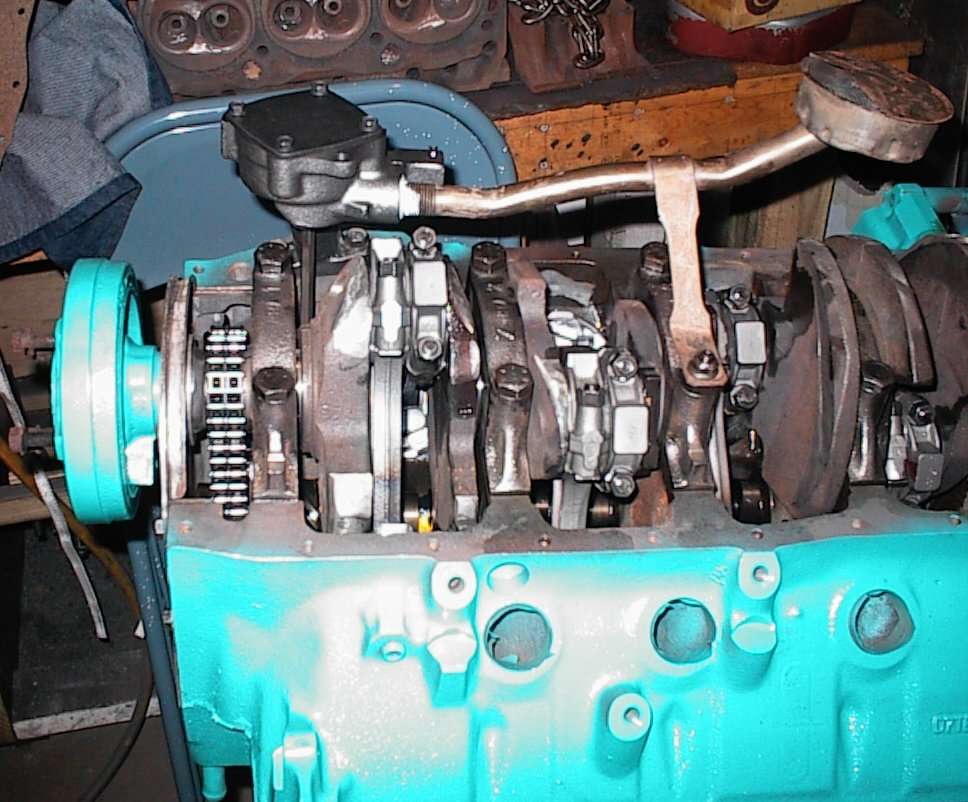

I do this mod to most Ford small blocks. The new oil passage directs a stream

of oil right to the distributor gear. Back in the old days it was no big

deal, but any more it seems that there are way too many new cams with gear

tooth problems, so anything that might keep an engine from coming back is

good.

I made a whole set of fancy hex drivers out of fluted bar stock and cut-off

Allen wrenches. Trick, eh?

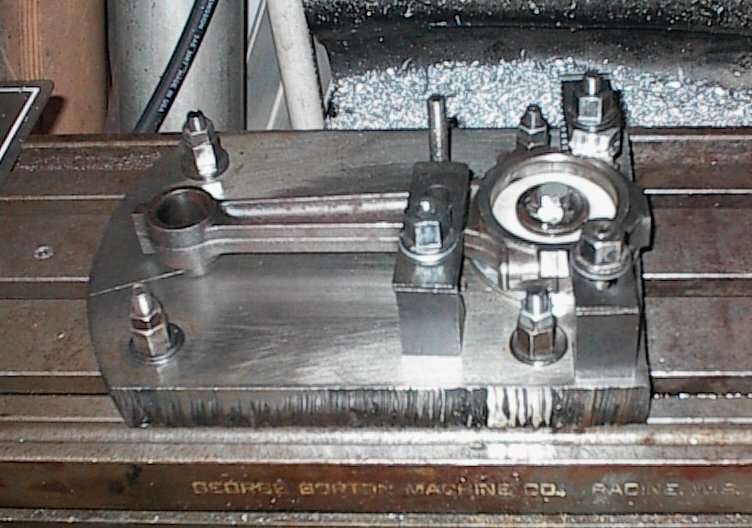

Checking valve-to-piston clearance. The pistons stick out of the bore .015".

If you have the urge to do one of these engines, use the aftermarket 1.43" pin

height pistons, not standard 350 Chevy pistons like these. You won't have to

cut .100" off the pistons tops!

The "P/S" marking means passenger side; these particular pistons have offset

pins for quiet running, so the valve notches will be on opposite sides on each

bank.

My flycutting rig is for parallel valves, so I wound up having to plunge a

little deeper and feather the cuts over with the Dremel and a sanding roll.

It's not like I was worried about conserving compression or anything...

It turned out that the 2V plenum was just big enough open up to a

Holley four barrel. It looked like Ford had designed it to go either way,

then only made two barrel intakes. Some of the filled-in area was over two

inches thick!

I have more shots of the project - flame-cutting the carb flange, welding in pieces to adapt it to the intake, porting the plenum, etc., but they're still on 35mm film in the camera. Whenever I finish the roll and have it developed I'll scan 'em and post 'em.

That's the kind of thing that happens when you own a racing engine shop, and

then you have someone else build an engine for your truck because you don't

have time to do it yourself.

The snorkels are screwed or riveted on, and you can add another. Some Fox body cars had an aluminum version of this housing that was slightly lower profile, and the one on the carbureted Mustang GTs had two snorkels already.

These things beat the hell out of those doofus open element "hot rod" air

filters. Why would you want to suck in all that 200+F underhood air? Just to

have something shiny when you have the hood up?

============================================================================

============================================================================

MAXIMUM OVERDRIVE RACING ENGINES

434 Ford stroker for Kenney Moore, Traskwood AR

completed 06/18/01

warranty: If it breaks, you get to keep all the pieces you can find.

*****

400 Ford stroked to 4.150", .080 overbore (434 CID)

Competition Cams 268H High Energy cam

Ford 351C-2V cylinder heads

Compression:

890 cc swept volume per cylinder (bore/stroke 4.080/4.150)

78 cc nominal chamber volume

- 3 cc +.015" deck

7.3 cc .035 gasket

5 cc valve notches (estimated)

--------

87.3 cc total clearance volume

890+87.3 = 977.3 total volume

977.3/87.3 = 11.2:1 CR

*****

===========================================================================

COMPONENTS ---------------------------------------------------------------

crankshaft:

Ford 400M casting

stroked to 4.150"

mains Clevite 77

main bearing clearance .0015"

rods 2.125" Ford 240/6 standard

polished journals

balanced 28oz (drill only)

pistons:

Silv-O-Lite 8-1436+.080

350 Chevy, milled tops

piston measured 1.538", .245" top land

cut .100" off

new top ring land .140" thick

flat top with four cast valve reliefs

fifth valve relief cut for Cleveland intake valve

4.080 diameter

wristpin offsets to quiet side

pistons flycut for 2V Cleveland heads

minimum .100" valve/piston clearance intake, .200" exhaust

CBC2 ceramic coated decks

+.015" deck height

rings:

standard small block Chevy. 4.080, Hastings, moly top

oil scrapers installed flex up

gaps:

#1 .031

#5 .028 .027

.028 .035/.030

.028/.032

#2 .032

#6 .035 .028

.034 .035/.033

.028/.038

#3 .028

#7 .034 .028

.033 .038/.034

.035/.033

#4 .028

#8 .032 .026

.028 .026/.028

.030/.032

rods:

Ford 240 Six, 6.79"

narrowed big ends to .895

pin ends honed out to .925 (.002 press for .927 pins)

rod side clearances .012, .012, .010, .014 (1-4)

resized big ends (minimum size)

chamfered sides of big ends

Michigan 77 rod bearings, 240/6, standard width

stock bolts

new ARP nuts

block:

400M block casting

bored .080

honed to .002" piston/wall clearance

#600 finish (ultra smooth)

2 piece rear main seal (RTV around edges)

new core plugs (RTV)

new cam bearings (Clevite 77)

tapped, .060" restrictors in cam oilways, .125" in p/s lifter oilway

oilway radiused at oil filter bend

all threaded holes chased

heads:

Ford 351C-2V

new .015" oversize EngineTech valves, single groove

2.06" intake / 1.65" exhaust

exhaust valves ceramic coated

intake and exhaust valves 20 degree back cut

exhaust valve faces radiused

new Competition Cams pn 743-16 chrome moly retainers 1.460"

new Competition Cams pn 940-16 dual valve springs 1.460"

guide clearance .002-.0025; some are 1/2" iron repair guides

three angle valve job, .065/.080 intake/exhaust seats

standard 11/32 single groove stamped keepers

deep umbrella seals, .050" int. / .038" exh. clearance at full lift

1.812" spring installed height

all threaded holes chased

cam:

Competition Cams 268H High Energy hydraulic pn 32-221-3

268/268 @ .006" (218/218 @ .050")

.494/.494 valve lift (.2853/.2853 lobe lift)

110 lobe center

opens closes

intake 28 BTDC 60 ABDC

exhaust 68 BBDC 20 ATDC

recommended install on 106 intake centerline, closest keyway position

was 107, used that

Competition Cams cam lube used for assembly lube

pushrods:

new SBI 5/16", stock replacements, pn 190-1417

rockers:

stock pedestal type, tips resurfaced

iron pedestals

separate sheet metal oil deflectors

timing set:

dual roller

cam chain index +0 (degreed in at 1 degree advanced)

two piece fuel pump eccentric

oil slinger on snout of crank

oiling:

new Melling M-84 high volume oil pump, 1.1" rotor height

stock 4wd pickup, Teflon pipe dope on threads

stock 4wd oil pan

harmonic balancer:

checked TDC, OK

intake:

Ford 400M iron, modified to four barrel flange

miscellaneous:

paint Rust-Oleum Mediterrenean Teal #7740 over red primer

===========================================================================

assembly lubricants:

rod bearings: 30wt ND

rings: Unilube two stroke oil

cylinder walls: 30wt oil

piston skirts: 30wt oil

wrist pins: Mobil 1 5w30

head bolts - threads: 30wt oil

main bolts - threads: 30wt ND

head, main bolts - under head: ARP moly grease

rod bolts: 30wt oil

cam bolt: 30wt oil

cam retainer plate bolts: 30wt oil

cam lobes: Competition Cams cam lube

cam journals: Competition Cams cam lube

cam distributor drive gear: Competition Cams cam lube

cam retainer plate/sprocket: Competition Cams cam lube

crankshaft rear oil seal: Mobil 1 5w30

===========================================================================

Stewart-Warner Model 2000 Industrial Balancer

balance:

(reciprocating)

519 big end (narrowed)

519 big end (narrowed)

53 bearing

53 bearing

(rotating)

552 piston (flycut)

148 wristpin

61 rings

187 pin end (honed .927)

---

2092 grams bob weight

setup RPM: 710

balance RPM: 590

front balance: .01 oz-in

rear balance: .01 oz-in

8 spins to completion

balance was drill-only

balanced for 28oz damper and flywheel

===========================================================================

TORQUE SPECIFICATIONS -----------------------------------------------------

--------torque---------------spec-----------thread---lube------------------

rod bolts

torqued to 45 ft-lb (Ford spec 45) 3/8-24 oil

main cap bolts

torqued to 100 ft-lb (Ford spec 95-105) 1/2-13 oil

note: 1) use moly grease under bolt head

2) step 1: 50 ft-lb

step 2: 80 ft-lb (reverse pattern)

step 3: 100 ft-lb (reverse pattern)

head bolts

torqued to 100 ft-lb (Ford spec 95-105) 1/2-13 oil

note: 2) block is blind tapped, no sealer needed

3) step 1: 50 ft-lb

step 2: 70 ft-lb (reverse pattern)

step 3: 100 ft-lb (reverse pattern)

damper (harmonic balancer) bolt

(Ford spec 70-90) 5/8-18 oil

note: use automatic transmission fluid as lubricant when pressing damper on

intake manifold bolts

(Ford spec 23-25) 5/16-18 sealer

note: 1) see drawing for pattern

exhaust manifold bolts

(Ford spec 18-24) 5/16-18 antiseize

note: 1) see drawing for pattern

rocker studs

timing chain sprocket bolt

torqued to 40 ft-lb (Ford spec 40-45) 3/8-16 oil

cam retainer plate

torqued to 10 ft-lb (Ford spec 9-12) 1/4-20 oil

oil pan bolts

(Ford spec 7-9) 1/4-20 dry

(Ford spec 9-11) 5/16-18 dry

oil drain plug

(Ford spec 15-25) 1/2-20 oil

water pump bolts

(torque 12-18) 5/16-18 antiseize

timing cover bolts

(torque 12-18) 5/16-18 antisieze

1/4 NPT threaded oilway plugs 1/4, 3/8 NPT Teflon tape

oil pump cover plate

(Ford spec 9-11) 1/4-20 Loctite 242

oil pump body

(torque 30-35) 3/8-16 Loctite 242

spark plugs

14mm oil

bottom pulley to damper

(Ford spec 35-50) oil

valve cover

(Ford spec 3-5) 1/4-20 oil

fuel pump to timing cover

(Ford spec 12-15) 5/16-18 oil

fan to water pump

(Ford spec 12-18) 5/16-24 antiseize

carburetor to intake

(Ford spec 12-15) 5/16-18 antiseize

SPECIAL PARTS ------------------------------------------------------------

modified parts: rods narrowed on big ends

rod pin ends opened up to .925"

pistons flycut for Cleveland valves

pistons decked to clear heads

intake and exhaust valves back cut

exhaust valve faces radiused

intake converted from 2bbl to 4bbl

Kenney:

bore and hone block

Dave:

stroke crank

narrow rods

hone pin ends

resize big ends

glass bead rods

balance rods

mill pistons

balance pistons

cut Cleveland valve reliefs

balance rotating assembly

clean lots of parts

mill, weld, grind to convert 2V intake to 4V

clean heads

ream guides

cut valve seats

back cut intake and exhaust valves

radius exhaust valves

check valve/piston clearance

check retainer/seal clearance

check rod side clearance

check stack

degree cam

verify TDC on harmonic balancer (OK)

gap rings

assemble heads and vacuum check

assemble long block

coat exhaust valves

coat pistons

Kenney got it in and fired it up. It was hard to start. It pinged badly even on premium gas and the timing backed way off. He put his compression gauge on it, and the gauge pegged at its far end - 300 PSI cranking compression! I had told him the cam was too small, but NNOOOO... well, it was his engine, so we have this big high compression stroker motor in a three-ton four wheel drive F350, and a little weiner cam to save gas?

The truck could not be driven as it was, so I found a 235 degree cam on a 108 that looked good; he has it on order. I'll let you know what happens...