brought to you by: Dave Williams

This page: www.bacomatic.org/~dw/fordv8/smallsix/smallsix.htm

Main page: http://www.bacomatic.org/~dw/index.htm

Last Updated: 16 Jul 2003

Author: Dave Williams; dlwilliams=aristotle=net

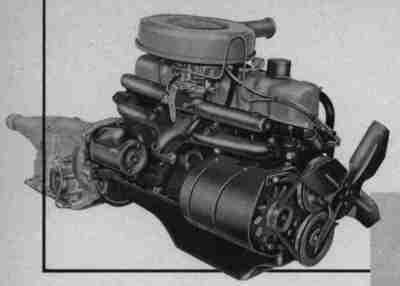

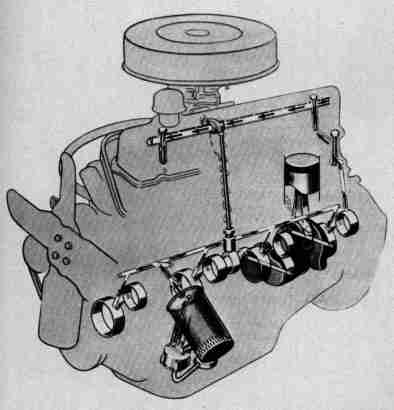

This was captioned as "144 Falcon Six" in a 1964 book. I was intrigued by the

huge shield over the generator, which I've never seen anywhere else. Was it

just a shield with a lot of air space, or was there some enormous optional

generator? The docs I have don't show any optional components like that.

This was captioned as "144 Falcon Six" in a 1964 book. I was intrigued by the

huge shield over the generator, which I've never seen anywhere else. Was it

just a shield with a lot of air space, or was there some enormous optional

generator? The docs I have don't show any optional components like that.

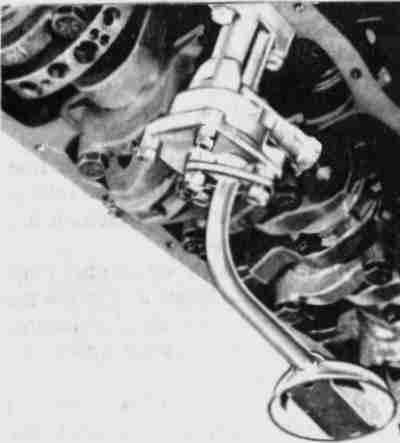

Right side view shows crankcase ventilation system, hollow-core four main

crank, downdrafted intake ports.

Right side view shows crankcase ventilation system, hollow-core four main

crank, downdrafted intake ports.

Displacement 144--------- 170--------- 200--------- 250--------- years to 73 69- rated HP 100 (1969) 115 (1969) 155 (1969) rated torque 156 (1969) 190 (1969) 240 (1969) compression 8.7:1 (1969) 8.8:1 (1969) 9.0:1 (1969) carburetion 1 barrel 1 barrel 1 barrel carb bore (1969) -- 1.448" 1.438" 1.688" carb. mfr. (1969) -- Carter Autolite Autolite carb bore (1971) -- 1.44" 1.69" 1.56" carb. mfr. (1971) -- Carter Carter Carter --- bore 3.502" 3.682" 3.682" stroke 2.94" 3.13" 3.91" main bearings 4 4 7 7 piston weight 16.5 oz 17.1 oz rod weight 18.65 oz 18.65 oz conrod length 4.715" 5.88" rod ratio wristpin offset 0.0625" 0.060" 0.090" weight 365 380 thrust bearing #3 #3 #5 #5 chamber size 59.4-62.4cc 59.4-62.4cc intake valve dia. 1.66" 1.66" exhaust valve dia. 1.39" 1.39" ====all===== length 31" width 17" height 20" bore spacing 4.08" firing order 1-5-3-6-2-4, #1 in front wristpin diameter 0.912" rod bearing length 0.77" rod brg. dia. 2.123" main brg. dia. 2.485" main brg. length 1.015" (thrust is 1.27")The Ford 'small six' was introduced in 1960 with the new Ford Falcon small car. It was almost 100 pounds lighter than the Mopar and GM sixes of the 1960s and was comparable in power despite being the smallest of the bunch at only 144 cubic inches or 2.3 liters.

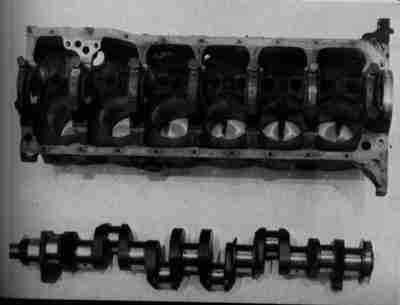

Since an inline six has a mirror-symmetrical crank and perfect primary and secondary balance, Ford was able to use only four main bearings without problems on the early engines. Ford then went to seven mains with the 200 and 250. The seven-main engines had less crankshaft deflection and less "Noise, Vibration, and Harshness" as Ford engineers called it. The seven-main blocks were heavier, but the cranks were lighter, so they were only a few pounds heavier than the four-main engines. Later 200s went back to four mains for weight and friction savings during the Gas Crunch years.

A silent chain was used to drive the camshaft. A bonded-rubber vibration damper was used on the forward end of the crank to reduce crankshaft stress.

The small sixes had tin-plated pistons and molybdenum-faced top rings. All engines had hydraulic lifters, cast nodular iron crankshafts, forged SAE 1041-H steel connecting rods, SAE 5015 steel wristpins, and cast aluminum pistons. The camshafts were "special cast iron", induction hardened and phosphate coated.

Though Ford kept the small six in production for over 20 years it had only brief interest to hot rodders, who promptly abandoned it when the V8 became available in the Falcon Sprint.

Yes, the 200's rods really were that short...

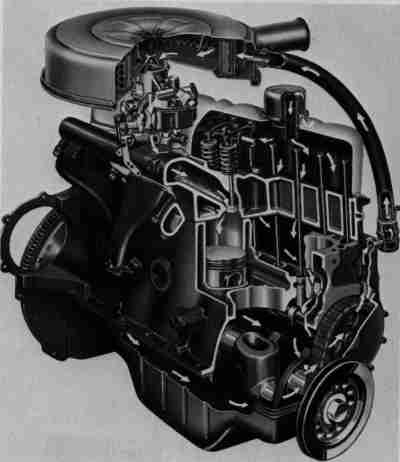

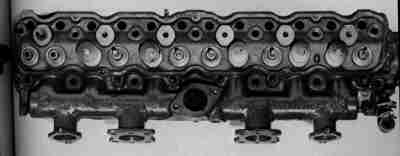

Cutaway of 144 inch Falcon six with solid lifters. Note the comapct

combustion chambers, large bore to stroke ratio, downdrafted intake port, and

large radius of the exhaust port. The *ports* actually were fairly good,

but the horrible log manifold cast into the head neutered attempts to make

decent power.

Cutaway of 144 inch Falcon six with solid lifters. Note the comapct

combustion chambers, large bore to stroke ratio, downdrafted intake port, and

large radius of the exhaust port. The *ports* actually were fairly good,

but the horrible log manifold cast into the head neutered attempts to make

decent power.

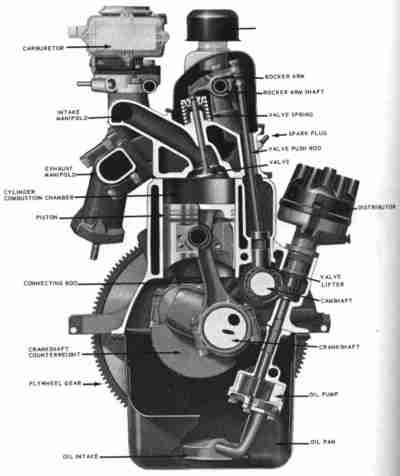

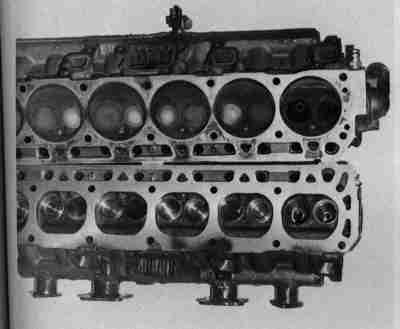

This cutaway of a 1968 200 six shows the good exhaust port shape. This is a

hydraulic lifter engine. Ford opened up the port and valve sizes in 1965,

though the 144 inch engines had the smallest combustion chambers.

This cutaway of a 1968 200 six shows the good exhaust port shape. This is a

hydraulic lifter engine. Ford opened up the port and valve sizes in 1965,

though the 144 inch engines had the smallest combustion chambers.

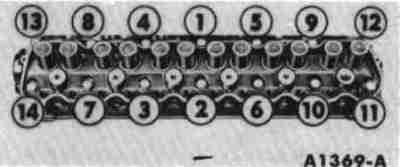

Small Six head bolt torque pattern. Torque was 55, 65, 75 ft-lbs in steps.

Small Six head bolt torque pattern. Torque was 55, 65, 75 ft-lbs in steps.

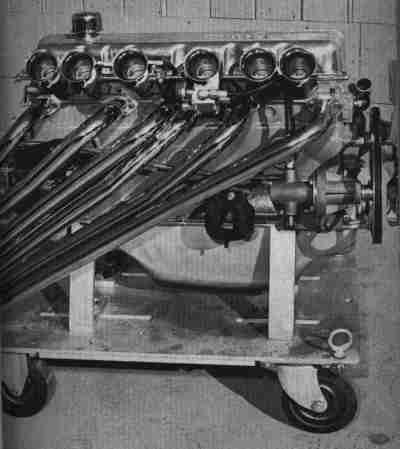

This Falcon 144 was built by Bill Stroppe & Associates (one of Ford's skunk

works) in 1961 or 1962. It was bored to 156 inches and the head was reworked

to accept Hilborn injectors, larger ports and valves.

This Falcon 144 was built by Bill Stroppe & Associates (one of Ford's skunk

works) in 1961 or 1962. It was bored to 156 inches and the head was reworked

to accept Hilborn injectors, larger ports and valves.

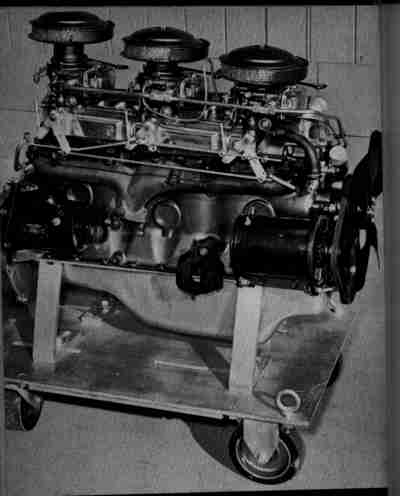

3x1bbl adapter and progressive linkage by Stroppe, same general time frame.

3x1bbl adapter and progressive linkage by Stroppe, same general time frame.

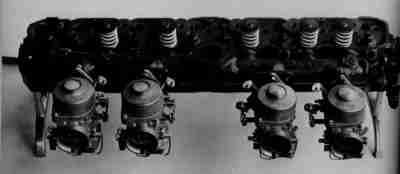

Ak Miller fangle circa 1967. Four 37mm Keihin constant velocity carburetors

from Honda 450 motorcycles were attached to stubs brazed to the cylinder head.

With these, milling the head .060, and the header, rear wheel horsepower went

from 65 to 125.

Ak Miller fangle circa 1967. Four 37mm Keihin constant velocity carburetors

from Honda 450 motorcycles were attached to stubs brazed to the cylinder head.

With these, milling the head .060, and the header, rear wheel horsepower went

from 65 to 125.

Fuel pressure regulator was necessary as the Keihins were designed for gravity

feed. Blockoff plate covers original carburetor mounting pad.

Fuel pressure regulator was necessary as the Keihins were designed for gravity

feed. Blockoff plate covers original carburetor mounting pad.

Miller found the chokes were never needed with the Keihins, so he removed them

to gain a couple more CFM of airflow.

Miller found the chokes were never needed with the Keihins, so he removed them

to gain a couple more CFM of airflow.

Top view. 260 V8 1-piece valve retainers and springs were fitted in place of

the stock 2-piece retainers and wimpy springs.

Top view. 260 V8 1-piece valve retainers and springs were fitted in place of

the stock 2-piece retainers and wimpy springs.

Bottom view of milled head with stubs. Note dual bolt pattern for inner

stubs, which could carry a pair of S.U. carburetors instead of Keihins.

Bottom view of milled head with stubs. Note dual bolt pattern for inner

stubs, which could carry a pair of S.U. carburetors instead of Keihins.

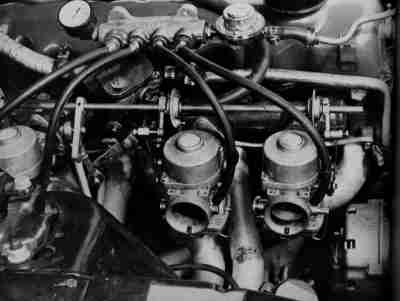

Two S.U. HD-6 1-3/4" carburetors turned out to be quite satisfactory. Note

balance tube between stub manifolds. Fuel economy was substantially better

than stock.

Two S.U. HD-6 1-3/4" carburetors turned out to be quite satisfactory. Note

balance tube between stub manifolds. Fuel economy was substantially better

than stock.

This nicely detailed 170 uses six Suzuki GS550 constant-velocity carbs. With

a six carb setup like this the stock log manifold functions only as a

connecting tube and plenum like the log on an MG or Jaguar inline engine.

This nicely detailed 170 uses six Suzuki GS550 constant-velocity carbs. With

a six carb setup like this the stock log manifold functions only as a

connecting tube and plenum like the log on an MG or Jaguar inline engine.

Offy three-carb conversion adapter for '70 and later small sixes.

Offy three-carb conversion adapter for '70 and later small sixes.

Offy three-carb conversion adapter for '61-'69 small sixes.

Offy three-carb conversion adapter for '61-'69 small sixes.

Ford Australia got the small six the same time the USA did. The small six was

also the baseline engine for the Falcon. In the USA the Falcon was canceled

in 1970; in Australia it lived on. The base engine was the 250 CID (4.1 L)

small six, but the 351 Cleveland cars got all the glory. On December 22,

1982, Ford Australia made the last of their V8s. The only available engine in

the Falcon became the 4.1.

Ford Australia got the small six the same time the USA did. The small six was

also the baseline engine for the Falcon. In the USA the Falcon was canceled

in 1970; in Australia it lived on. The base engine was the 250 CID (4.1 L)

small six, but the 351 Cleveland cars got all the glory. On December 22,

1982, Ford Australia made the last of their V8s. The only available engine in

the Falcon became the 4.1.

The Down Under 250 had mutated quite far from its humble Detroit beginnings

and was a quite efficient and capable engine, partly due to its spiffy

crossflow aluminum head. Other than the usual grumbling things would likely

have proceeded smoothly, particularly since a new fuel-injected version of the

4.1 shipped in early 1983. However, Ford Australia's management was just as

moronic as the bozoids in Detroit, and they issued various press releases

claiming the cars with the 4.1 were just as fast as the V8 cars. Which they

weren't, not by anyone's tests other than Ford's. Ford got crucified over

that, and the poor 4.1 got caught in the shitstorm.

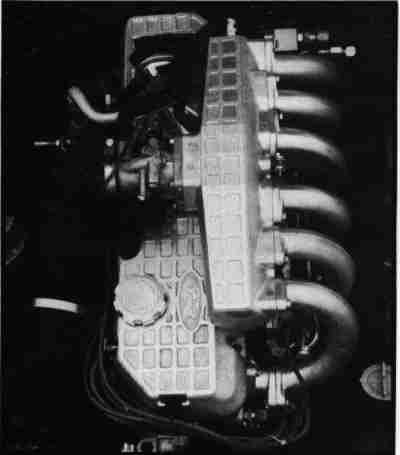

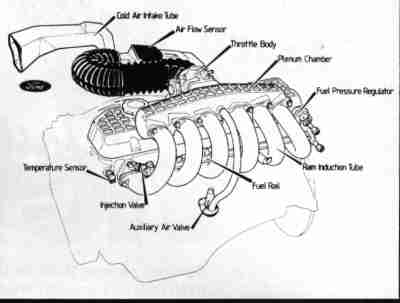

These are the basic components of the Australian 250's EFI. It's a Bosch LE2

Jetronic. Ford claimed they spent 2.5 million dollars and two years

"developing" the system. Bosch likely did the work for them for free;

Australia didn't have much in the way of smog controls in 1983, and they could

probably have just used the maps from any big six LE2 installation with a

tweak here and there.

These are the basic components of the Australian 250's EFI. It's a Bosch LE2

Jetronic. Ford claimed they spent 2.5 million dollars and two years

"developing" the system. Bosch likely did the work for them for free;

Australia didn't have much in the way of smog controls in 1983, and they could

probably have just used the maps from any big six LE2 installation with a

tweak here and there.

Specs were 4089cc, 93.5 x 99.3 BxS, 8.8:1 CR, 111Kw @ 3800, 325Nm @ 2800. A

kilowatt (Kw) is about 1.25 of a horsepower, depending on what kind of

horsepower you're talking about. The other... I'll do kilogram-meters, but the

ISO Nazis can cram their fig newtons up their asses.

The small sixes had a very simple oiling system. A lengthwise drilling to the

four or seven mains, depending on the model, which also fed the hydraulic

lifters. A vertical passage to the rocker shaft, with timed oil ports on the

rockers to squirt oil at the upper pushrod sockets. The pushrods were solid

instead of the more-common oil-filled tubes.

The small sixes had a very simple oiling system. A lengthwise drilling to the

four or seven mains, depending on the model, which also fed the hydraulic

lifters. A vertical passage to the rocker shaft, with timed oil ports on the

rockers to squirt oil at the upper pushrod sockets. The pushrods were solid

instead of the more-common oil-filled tubes.

Here's a really nice picture of the small six's oil pump. It sucks up through

the bottom cover plate instead of through making multiple jogs through the

pickup tube and pump housing. Why aren't the V8 pumps like this? It looks

like a very efficient layout.

Here's a really nice picture of the small six's oil pump. It sucks up through

the bottom cover plate instead of through making multiple jogs through the

pickup tube and pump housing. Why aren't the V8 pumps like this? It looks

like a very efficient layout.

The seven-main 200 crank carried only four counterweights. Though the engine

as a whole was in balance, the lack of center counterweights put a bending

couple on the crankshaft. In practice it didn't seem to hurt anything.

The seven-main 200 crank carried only four counterweights. Though the engine

as a whole was in balance, the lack of center counterweights put a bending

couple on the crankshaft. In practice it didn't seem to hurt anything.

The four-main crankshafts were fully counterweighted. The seven-main crank is

lighter than the four-main cranks due to its partial counterweighting.

Ak Miller welded up this header from bits of tubing in 1967. You can still

buy headers for the small six from the usual sources.

Ak Miller welded up this header from bits of tubing in 1967. You can still

buy headers for the small six from the usual sources.

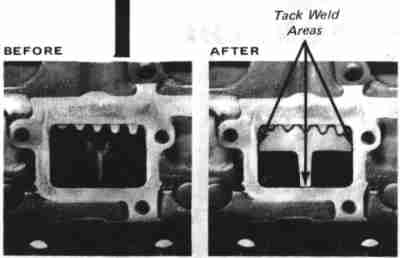

Clifford Research sells this cast iron exhaust port divider. It's supposed to

make the flow of the two center cylinders equal to the flow of the four

outers. They bundle the divider with each header they sell, and they also

sell it separately.

Clifford Research sells this cast iron exhaust port divider. It's supposed to

make the flow of the two center cylinders equal to the flow of the four

outers. They bundle the divider with each header they sell, and they also

sell it separately.

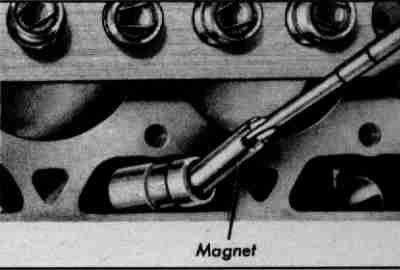

One of Ford's economies when building the small six was the elimination of the

usual sheet metal access cover on the side of the block. To remove a lifter,

you were supposed to remove the cylinder head first, then reach down into the

block with a magnet and pull the lifter out. Other than the hassle of

removing the head, this idea would only work when the engine was new or

freshly rebuilt; after that the varnish buildup on the bottom of the lifter

made it impossible to remove with a magnet. Various tool companies made tools

that tried to grab onto the snap ring groove in the lifter, but often the only

way to remove a stubborn lifter was to remove the engine, flip it upside down,

remove the oil pan and camshaft, and drive the lifter out with a punch.

One of Ford's economies when building the small six was the elimination of the

usual sheet metal access cover on the side of the block. To remove a lifter,

you were supposed to remove the cylinder head first, then reach down into the

block with a magnet and pull the lifter out. Other than the hassle of

removing the head, this idea would only work when the engine was new or

freshly rebuilt; after that the varnish buildup on the bottom of the lifter

made it impossible to remove with a magnet. Various tool companies made tools

that tried to grab onto the snap ring groove in the lifter, but often the only

way to remove a stubborn lifter was to remove the engine, flip it upside down,

remove the oil pan and camshaft, and drive the lifter out with a punch.