Author: Dave Williams; dlwilliams=aristotle=net

David DeHaven wanted a big block for his '49 Ford, so I sold him one of mine. It was a 1973 460 from a Lincoln Continental. It had sat out in the weather for a while, but had low miles and negligible wear. I had driven the car before pulling the engine out.

This was just a disassemble, clean, re-ring, and reassemble job. This engine had the marine-type super-open-chamber heads. I swapped them for a pair of C9VE high compression 429 heads, which needed a little work; that's the only machine work that went into this one.

There's nothing unique about this job; I take pictures of everything now that I have a digital camera, and I figured Dave would want the pictures, so I assembled them into a quickie web page. Almost all the work on this one was simply cleaning, measuring, and painting.

I took these pictures to show where all the accessories went.

I took these pictures to show where all the accessories went. Check out the enormous stamped steel bracket for the power steering pump and

air conditioning compressor. That's a Harrison A6 compressor, same as

Cadillacs and other GM products used.

Check out the enormous stamped steel bracket for the power steering pump and

air conditioning compressor. That's a Harrison A6 compressor, same as

Cadillacs and other GM products used.

The alternator and its brackets mounted on the left; they've already been

removed in this shot.

The alternator and its brackets mounted on the left; they've already been

removed in this shot.

On the other side, where you can't see it, is a Delco starter. At least this

engine had a Motorcraft carburetor instead of a Quadrajet. For some strange

reason, Ford used a lot of GM accessories in some early '70s models.

On the other side, where you can't see it, is a Delco starter. At least this

engine had a Motorcraft carburetor instead of a Quadrajet. For some strange

reason, Ford used a lot of GM accessories in some early '70s models.

Large vacuum servo for cruise control.

Large vacuum servo for cruise control.

You can see the first casualty of storing things outside - I broke the

distributor housing off when trying to remove it, even after soaking it in

penetrating oil. Ford uses an O-ring to seal the housing, but water gets down

in the crack above the O-ring and the aluminum oxidizes, getting a deathgrip

on the block.

You can see the first casualty of storing things outside - I broke the

distributor housing off when trying to remove it, even after soaking it in

penetrating oil. Ford uses an O-ring to seal the housing, but water gets down

in the crack above the O-ring and the aluminum oxidizes, getting a deathgrip

on the block.

On the stand, stripping it down. It was in amazingly good shape; everything

miked out well within service limits. I drove the broken distributor out

through the bottom.

On the stand, stripping it down. It was in amazingly good shape; everything

miked out well within service limits. I drove the broken distributor out

through the bottom.

Nice clean cylinders with no rust.

Nice clean cylinders with no rust.

The block just came out of the hot tank. Now for lots of wire wheeling,

tapping all the holes, and all the rest of the tedious work you have to do...

The block just came out of the hot tank. Now for lots of wire wheeling,

tapping all the holes, and all the rest of the tedious work you have to do...

The bores were within spec, so all I did was run a soft hone through to create

a fine crosshatch for the new rings to seat on.

The bores were within spec, so all I did was run a soft hone through to create

a fine crosshatch for the new rings to seat on.

The thrill of drilling out all the oil gallery plugs... all the cores I come

across, they're in so tight they just strip when trying to remove them. Yes,

I tried the Allen bit first. Yes, it stripped...

The thrill of drilling out all the oil gallery plugs... all the cores I come

across, they're in so tight they just strip when trying to remove them. Yes,

I tried the Allen bit first. Yes, it stripped...

The weird angled section on the bellhousing pattern is the old M-E-L 430-462

bellhousing pattern. The top bolts were different on the M-E-L. I never

quite figured out why the 429/460 got both the M-E-L and their own

special bolt pattern, but Ford does a lot of that sort of thing.

The weird angled section on the bellhousing pattern is the old M-E-L 430-462

bellhousing pattern. The top bolts were different on the M-E-L. I never

quite figured out why the 429/460 got both the M-E-L and their own

special bolt pattern, but Ford does a lot of that sort of thing.

Once you drill through the plug, you hammer a cape chisel in to get a good

bite. EZ-outs seldom work here.

Once you drill through the plug, you hammer a cape chisel in to get a good

bite. EZ-outs seldom work here.

Plugs removed, and I've already run a tap through to clean up the threads.

Not that you care about any of this, but it's one of those suck jobs that

simply has to be done. Lots of crud builds up behind the plugs in an old

engine.

Plugs removed, and I've already run a tap through to clean up the threads.

Not that you care about any of this, but it's one of those suck jobs that

simply has to be done. Lots of crud builds up behind the plugs in an old

engine.

Same deal for the water drain plugs.

Same deal for the water drain plugs.

I wire wheeled the carbon off the pistons, taking care to avoid the ring

grooves, which I cleaned with a piece of broken ring. Then they got washed

and put outside to dry.

I wire wheeled the carbon off the pistons, taking care to avoid the ring

grooves, which I cleaned with a piece of broken ring. Then they got washed

and put outside to dry.

New parts from Clevite, Fel-Pro, and Speed-Pro. When taking it apart I

dropped one piston and broke the skirt; a single replacement piston cost $40.

[sigh] I pressed the broken one off the rod and installed the new one.

New parts from Clevite, Fel-Pro, and Speed-Pro. When taking it apart I

dropped one piston and broke the skirt; a single replacement piston cost $40.

[sigh] I pressed the broken one off the rod and installed the new one.

Here we are, starting reassembly. Each cam bearing goes in its particular

spot. Quite often, 429/460 cam journals are out of alignment. I have a

reamer tool to scrape the bearings, but this engine didn't need it.

Here we are, starting reassembly. Each cam bearing goes in its particular

spot. Quite often, 429/460 cam journals are out of alignment. I have a

reamer tool to scrape the bearings, but this engine didn't need it.

Next comes the crank, on its new bearings.

Next comes the crank, on its new bearings.

The flash makes it look odd, but it's ordinary Ford Blue. All the pistons are

in, now. It only too 25 ft-lb of torque to turn it over.

The flash makes it look odd, but it's ordinary Ford Blue. All the pistons are

in, now. It only too 25 ft-lb of torque to turn it over.

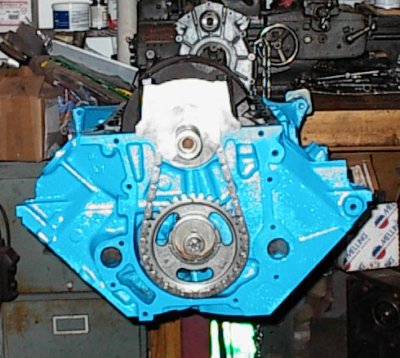

New timing chain...

New timing chain...

M A X I M U M O V E R D R I V E R A C I N G E N G I N E S

460 Ford for David DeHaven, Wichita Kansas

clean, inspect, reassemble

completed September 2003 (long block)

4.360 bore (std)

3.850 stroke (std)

460 CID, 7539cc (7.5 L)

approximate compression (from published figures):

76 cc combustion chamber (closed)

11 cc head gasket

5 cc -.020 deck

26 cc .235 x 3" dish

------

118 cc clearance volume

942 cc swept volume (4.36 x 3.85)

118 cc clearance volume

-------

1060 cc total volume

1060 / 118 = 8.9:1

warranty: if it breaks, you get to keep all the pieces you can find

============================================================================

Crank:

stock 460

polished journals

standard size mains Clevite MS-1039 P

.001-under rods Clevite CB-818 P-1

end play .0035"

Pistons:

7 stock Ford, dish top, 980 grams

1 Speed-Pro replacement (cylinder #4)

Rings:

Perfect Circle 50843CP standard size

5) .027 1) .028

.029 .025

.040/.039 .041/.040

6) .028 2) .026

.026 .024

.039/.039 .039/.039

7) .026 3) .024

.023 .025

.037/.038 .037/.038

8) .026 4) .024

.025 .022

.039/.040 .038/.038

Rods:

stock 460

side clearance:

pair 1) .011

2) .014

3) .014

4) .012

Block:

1973 460

new freeze plugs

new cam bearings

ball-honed bores

chased threads

Rust-Oleum Rusty Metal Primer

Heads:

C9VE (same as D0VE) closed chamber, from 429 CID engine

3-angle valve job

decked flat

new bronze guide liners

Valvetrain:

timing set: Clevite 3013

pushrods: stock Ford

stock 429 adjustable rockers, 1.73:1

Cam:

Summit hydraulic flat tappet SUM-3051

286/286 advertised

218/228 @.050, .503/.503", 110LC, ground 5 degrees advanced

events at .050:

IO 0 BTDC

IC 38 ABDC

EO 53 BBDC

EC -9 BTDC

Intake:

stock iron 460

Carburetor:

stock Motorcraft 4bbl

Miscellaneous:

turning torque 25 ft-lb without cam