Sandblasted, scrubbed with a toothbrush to remove any loose grit, thoroughly

rinsed, and drying. You have to get a fairly rough finish for the coatings to

stick properly.

Sandblasted, scrubbed with a toothbrush to remove any loose grit, thoroughly

rinsed, and drying. You have to get a fairly rough finish for the coatings to

stick properly.

Author: Dave Williams; dlwilliams=aristotle=net

Bruce wanted something to replace the ailing 3.8 in the Black Car, his '86 Buick Grand National. We decided on a large bore 4.1L block and various goodies. Nothing spectacular.

For what was supposed to be just a high quality rebuild, I sure ran into a lot of problems with this one. Nothing wanted to fit without its due share of attention. More than once, I wound up throwing a bag over it and working on something else while deciding how to solve various problems.

Bruce and I decided we wanted the compression ratio to be 7.5:1, figured out the dish volume, specified the dishes be CNC-machined to match the Buick chambers, standard-width Chevy rings, slot type pin oilers, and everything else standard Buick 4.1, for a 4 inch bore. The specifications were faxed to BRC. These were very expensive pistons - $650 for six.

When the pistons came in, the first thing I noticed was that the pistons had big round bowls instead of the combustion-chamber-shaped dishes I'd specified. We called up BRC, FAX in hand, and their attitude was basically, "we have your money, you have the pistons, go away." One of the reasons for going to custom pistons was to take advantage of all the extra quench available with the large 4.1 bore. Now we didn't even have as much as a stock 3.8.

Next, I noticed that they had drilled pin oiler holes to the oil ring grooves. This is common enough, but the FAX specified slot type oilers, which are better for turbo motors. Then I noticed the pistons had .927" Chevrolet pins instead of .939" Buick pins. Another call to BRC, which didn't achieve any satisfaction either, but at least I could express my dissatisfaction again.

BRC is not only incompetent, they're a bunch of assholes too.

Later, as I was assembling the long block, I found out they'd also munged the valve reliefs. The Buick has four exhaust valves on the left, two on the right. I had six left-hand pistons. Not only that, the reliefs weren't in the right place - the valves hit the sides of the reliefs. After staring at things for a while, I realized they had machined the reliefs to clear the valves in Stage 1 heads, which have the valves closer to the chamber centerline than stock heads. I said to hell with it and adjusted the reliefs with the die grinder. It wasn't worth calling up the assholes at BRC to complain again.

Sandblasted, scrubbed with a toothbrush to remove any loose grit, thoroughly

rinsed, and drying. You have to get a fairly rough finish for the coatings to

stick properly.

Sandblasted, scrubbed with a toothbrush to remove any loose grit, thoroughly

rinsed, and drying. You have to get a fairly rough finish for the coatings to

stick properly.

I didn't find out about the relief location problem until after they were coated, baked, polished, and hung on their rods.

Two pistons look like they have full-round dishes, but that's some weird

optical illusion. All six are the same.

Here we are, masked and ready to put the ceramic thermal barrier on the tops.

Here we are, masked and ready to put the ceramic thermal barrier on the tops.

The tops have been ceramic'd, I'd just started on the moly coating on the

sides when my airbrush quit. Frantic fumbling didn't show anything wrong -

there's just a valve, a pot, and a nozzle - so I grabbed a foam brush that was

handy and used that. The brush gave a perfectly serviceable finish, but it

wasn't nearly as pretty as the airbrush gives.

The tops have been ceramic'd, I'd just started on the moly coating on the

sides when my airbrush quit. Frantic fumbling didn't show anything wrong -

there's just a valve, a pot, and a nozzle - so I grabbed a foam brush that was

handy and used that. The brush gave a perfectly serviceable finish, but it

wasn't nearly as pretty as the airbrush gives.

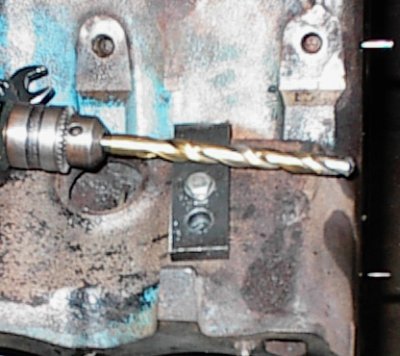

I've drilled the hole for the turbo oil return line, and now I'm tapping it.

It takes an amazing amount of force to turn a 1/2 NPT tap...

I've drilled the hole for the turbo oil return line, and now I'm tapping it.

It takes an amazing amount of force to turn a 1/2 NPT tap...

Tapping the oil galleries at the front of the block. The stock Buick has

push-in cup plugs here.

Tapping the oil galleries at the front of the block. The stock Buick has

push-in cup plugs here.

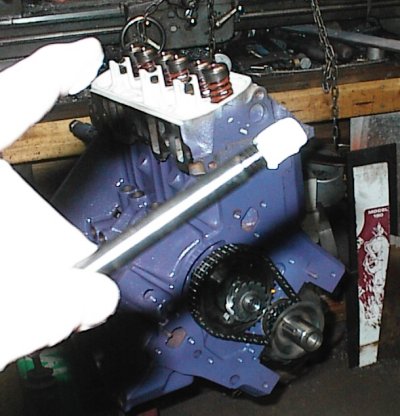

This shot with the penlight shows how short the distance is from the front of

the block to the main oil gallery. You need a shorter than standard plug to

avoid restriction in the oil flow.

This shot with the penlight shows how short the distance is from the front of

the block to the main oil gallery. You need a shorter than standard plug to

avoid restriction in the oil flow.

The other side isn't that critical; it just feeds the lifters, the the passage

is further back. Ford 351 Cleveland rear lifter gallery plugs are an odd size

which worked nicely in this application.

The other side isn't that critical; it just feeds the lifters, the the passage

is further back. Ford 351 Cleveland rear lifter gallery plugs are an odd size

which worked nicely in this application.

Retapping all the head bolt holes so the new ARP studs will screw in properly.

Retapping all the head bolt holes so the new ARP studs will screw in properly.

Retapping the mains for the same reason. The tap handle wouldn't swing down

in the block, so I used Vise-Grips. It doesn't take a lot of force when

you're just cleaning up the threads.

Retapping the mains for the same reason. The tap handle wouldn't swing down

in the block, so I used Vise-Grips. It doesn't take a lot of force when

you're just cleaning up the threads.

Since it was very convenient to tune the engine by cylinder pressure on a continual basis, instead of just using the indicator to diagnose a problem, some enterprising Diesel guys reasoned that since pressure was what made it all work, you could measure pressure anywhere. One nifty and inexpensive device was a hole drilled through the cylinder wall, just before the exhaust valve opening point. The higher the average pressure, the higher the end pressure... and the end pressure was under 300 PSI. Since the hole was uncovered on the intake stroke as well, it measured average cylinder pressure, not peak... which was just fine. One of the methods of rating an engine's power output is by its cylinder pressure - Brake Mean Effective Pressure, or BMEP. To get more than 150 PSI BMEP requires some sort of supercharging and/or exotic fuels.

The end-pressure indicator consisted of the port in the block, a tube to a receiving chamber with a drain cock, and an ordinary dial pressure gauge. Sizing of the tubes, orifices, and receiving chamber volume would determine how stable the gauge reading was.

The fancy indicators, of course, could tell you the instantaneous pressure anywhere in the engine's cycle, which let you diagnose all kinds of injection problems easily. The end-pressure system only gives you mean, or average, pressure. It's not as useful for diagnostics, but it is still very useful for tuning.

For all practical purposes, BMEP is horsepower; the higher the BMEP, the higher the horsepower. Now, with this simple gauge system, we don't know the exact relationship between cylinder pressure and rear wheel horsepower... but it doesn't matter. In engineering, this is what a friend of mine calls "The Al Bundy Algorithm." This is commonly expressed as, "Don't know, don't care." We're tuning for maximum cylinder pressure; whatever maximum actually is doesn't matter, because maximum is all we can get.

Bruce decided he wanted a BMEP port, so I added one to the block. You can skip the next sequence of images if you don't care.

Drag out a bunch of drills and taps...

Drag out a bunch of drills and taps...

Mark where to drill with a piece of tape, center punch, and drill a hole to

temporarily hold a drill fixture.

Mark where to drill with a piece of tape, center punch, and drill a hole to

temporarily hold a drill fixture.

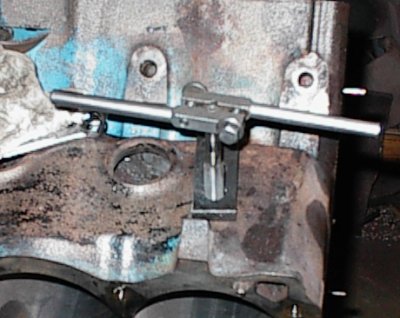

Tap 5/16-18, bolt the drill jig down. It's just a piece of 3/8" steel scrap

with a couple of holes, but it's enough to keep all the drills and taps lined

up straight.

Tap 5/16-18, bolt the drill jig down. It's just a piece of 3/8" steel scrap

with a couple of holes, but it's enough to keep all the drills and taps lined

up straight.

Next, we drill 5/16" through the outside of the water jacket.

Next, we drill 5/16" through the outside of the water jacket.

Next, we chuck a 5/16" end mill into the drill, reach through the 5/16" hole,

and carefully machine a 5/16" flat into the outside of the cylinder wall.

Next, we chuck a 5/16" end mill into the drill, reach through the 5/16" hole,

and carefully machine a 5/16" flat into the outside of the cylinder wall.

Next we open the jig up to 27/64 on the drill press, bolt it back down on the

block, and open the outside hole up to 27/64, which is the correct tap drill

size for a 1/2-20 fine thread.

Next we open the jig up to 27/64 on the drill press, bolt it back down on the

block, and open the outside hole up to 27/64, which is the correct tap drill

size for a 1/2-20 fine thread.

The jig is opened up to 1/2" on the drill press, reinstalled, and we tap 1/2"

for the bushing.

The jig is opened up to 1/2" on the drill press, reinstalled, and we tap 1/2"

for the bushing.

All the drilling and tapping is done. Finally!

All the drilling and tapping is done. Finally!

The bushing is a piece of 1/2-20 stainless steel threaded rod. I drilled a

5/16" hole most of the way through on the lathe, taper reamed the opening,

tapped 1/8-27 NPT, flipped it around, and put a 5/16"x.060" nose on the closed

side. Here, I'm cleaning up the 1/8-27 threads. Cranking down a pair of nuts

lets me hold it in the vise without damaging any threads.

The bushing is a piece of 1/2-20 stainless steel threaded rod. I drilled a

5/16" hole most of the way through on the lathe, taper reamed the opening,

tapped 1/8-27 NPT, flipped it around, and put a 5/16"x.060" nose on the closed

side. Here, I'm cleaning up the 1/8-27 threads. Cranking down a pair of nuts

lets me hold it in the vise without damaging any threads.

Now I've screwed a piece of threaded

rod into the temporary locating hole, and I'm getting ready to saw it off.

It's snug against the cylinder to provide a little extra support.

Now I've screwed a piece of threaded

rod into the temporary locating hole, and I'm getting ready to saw it off.

It's snug against the cylinder to provide a little extra support.

The block has been ground down to fresh metal, the jig plug is cut off flush,

and a pipe plug has been inserted into the bushing to have something to turn

it in with, and to protect the threads. A dab of epoxy went on the closed end

of the bushing.

The block has been ground down to fresh metal, the jig plug is cut off flush,

and a pipe plug has been inserted into the bushing to have something to turn

it in with, and to protect the threads. A dab of epoxy went on the closed end

of the bushing.

At this point, the cylinder wall has a flat, but no hole, and the hole in the

bushing doesn't go all the way through either.

Jumping ahead a bit, the bushing and plug have been welded, the welds dressed

with the grinder, and epoxy smeared around, just in case.

Jumping ahead a bit, the bushing and plug have been welded, the welds dressed

with the grinder, and epoxy smeared around, just in case.

Finally, I reached in through the bushing with a .087" drill bit and drilled

all the way through into the cylinder. I touched up the hole with a

countersink.

Finally, I reached in through the bushing with a .087" drill bit and drilled

all the way through into the cylinder. I touched up the hole with a

countersink.

It would have been best if the block hadn't been bored and honed yet, but it

worked out okay this way.

There was a freeze plug rattling around inside the water jacket, left by a

previous rebuilder. I fought with it for an hour. My buddy Doug dropped by

and fished it out in about three minutes. Sometimes you feel like slapping

the sh*t out of someone, just because...

There was a freeze plug rattling around inside the water jacket, left by a

previous rebuilder. I fought with it for an hour. My buddy Doug dropped by

and fished it out in about three minutes. Sometimes you feel like slapping

the sh*t out of someone, just because...

New brass plugs in the sides. The ones in the rear are already installed.

New brass plugs in the sides. The ones in the rear are already installed.

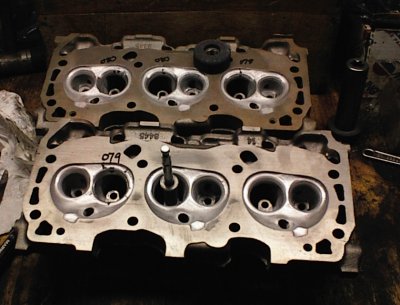

Bruce had polished the combustion chambers and done some porting on the heads

before he brought them down. Pretty, aren't they?

Bruce had polished the combustion chambers and done some porting on the heads

before he brought them down. Pretty, aren't they?

Not for long, as I get ready to fire up Mr. Sandblaster...

Not for long, as I get ready to fire up Mr. Sandblaster...

The combustion chambers and exhaust ports got blasted to hold the thermal

barrier coating.

The combustion chambers and exhaust ports got blasted to hold the thermal

barrier coating.

The Buick V6s have a bunch of passages drilled from the exhaust port bowls,

across the width of the head, and through the manifold face. On carbureted

engines, two of these passages are used for the exhaust crossover under the

intake. For injected cars, only one port is connected to the intake, for EGR.

All the rest are blocked by the gasket.

The Buick V6s have a bunch of passages drilled from the exhaust port bowls,

across the width of the head, and through the manifold face. On carbureted

engines, two of these passages are used for the exhaust crossover under the

intake. For injected cars, only one port is connected to the intake, for EGR.

All the rest are blocked by the gasket.

After much head scratching and belly-button inspecting, we decided the maze of

drillings was intended to speed engine warm-up for emissions purposes. We

certainly didn't need to put any more heat into the water jacket with this

particular engine, so I machined a bunch of plugs on the lathe to block off

all the holes, since Bruce isn't using EGR. Some of the holes were stepped,

so the plugs could be simply driven in with epoxy; the large ones in the

middle intersected, so I beveled one plug, which was retained by the one that

passed it.

Here, I've welded the intake faces there the plugs were driven in, slopped

some epoxy in to neaten things up, and I have this head propped so the epoxy

won't drool away before it sets up.

Here, I've welded the intake faces there the plugs were driven in, slopped

some epoxy in to neaten things up, and I have this head propped so the epoxy

won't drool away before it sets up.

Remember that one plug that slid right in? It's epoxied along its length and

welded at the manifold end, but paranoia is your friend. I'm drilling a hole

for a roll pin, just for general belt-and-suspenders-ness.

Remember that one plug that slid right in? It's epoxied along its length and

welded at the manifold end, but paranoia is your friend. I'm drilling a hole

for a roll pin, just for general belt-and-suspenders-ness.

Roll pin installed. I ground it off flush, staked it, and then covered the

area with epoxy. Yes, I am paranoid. Why do you ask?

Roll pin installed. I ground it off flush, staked it, and then covered the

area with epoxy. Yes, I am paranoid. Why do you ask?

Here we are, all coated...

Here we are, all coated...

And detaping...

And detaping...

I baked them in the oven in the house; the ceramic

doesn't outgas anything noxious.

Polishing the combustion chambers and ports with 0000 steel wool. The ceramic

shines up bright silver after the surface film is scrubbed away.

Polishing the combustion chambers and ports with 0000 steel wool. The ceramic

shines up bright silver after the surface film is scrubbed away.

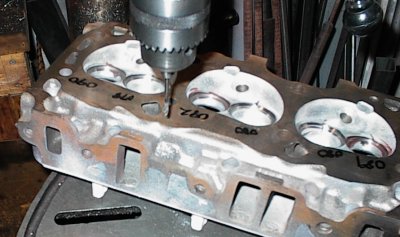

Now I'm cutting new valve seats. The ceramic and resin tend to gum up the

stones, so they have to be sharpened after every seat. The stock valve guides

were in fine shape, astonishingly enough!

Now I'm cutting new valve seats. The ceramic and resin tend to gum up the

stones, so they have to be sharpened after every seat. The stock valve guides

were in fine shape, astonishingly enough!

Standard three-angle valve job. The numbers in felt tip are the seat widths.

I cut the exhaust seats wider than usual to help transfer heat from the

exhaust valve to the head. Every little bit helps when you're trying to avoid

detonation. On the flow bench a narrower seat will usually pass more air, but

my view is that temperature management is more important on a turbo motor.

Standard three-angle valve job. The numbers in felt tip are the seat widths.

I cut the exhaust seats wider than usual to help transfer heat from the

exhaust valve to the head. Every little bit helps when you're trying to avoid

detonation. On the flow bench a narrower seat will usually pass more air, but

my view is that temperature management is more important on a turbo motor.

Mask off the guides and shaft mounts, and paint with white epoxy.

Mask off the guides and shaft mounts, and paint with white epoxy.

First coat of paint on the outside next...

First coat of paint on the outside next...

Somehow, the combination of stock Buick valves, Chevy springs, and Chevy

titanium retainers wound up substantially short on spring installed height.

So I cut the valve seats down with this special cutter until everything was

correct. This is very rare; normally, you wind up shimming the springs, not

cutting the seats!

Somehow, the combination of stock Buick valves, Chevy springs, and Chevy

titanium retainers wound up substantially short on spring installed height.

So I cut the valve seats down with this special cutter until everything was

correct. This is very rare; normally, you wind up shimming the springs, not

cutting the seats!

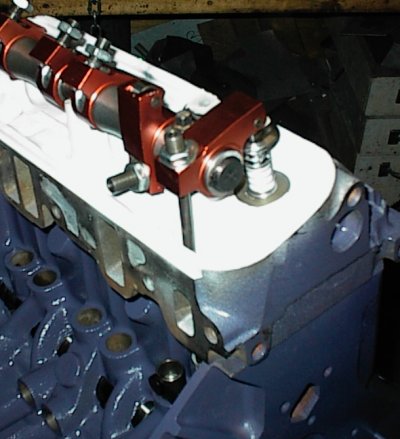

Setting up to check the rocker geometry. The roller rockers contacted the

valve stems just off center. They were within the useable range, but since we

were buying new pushrods anyway, shorter to compensate for the hydraulic

roller lifters, tried adjusting the pushrod length to center the wipe

patterns. After much experimentation, I finally realized that the pushrod

length doesn't do squat when you have shaft mounted rockers.

Setting up to check the rocker geometry. The roller rockers contacted the

valve stems just off center. They were within the useable range, but since we

were buying new pushrods anyway, shorter to compensate for the hydraulic

roller lifters, tried adjusting the pushrod length to center the wipe

patterns. After much experimentation, I finally realized that the pushrod

length doesn't do squat when you have shaft mounted rockers.

Well, DUH [sigh]

Plenty of room for the valves vertically, but we have side contact.

Plenty of room for the valves vertically, but we have side contact.

Just another shot of the test setup.

Just another shot of the test setup.

I clayed each piston in turn, until I realized the left/right hand problem and

the BRC piston screwup. A little work with Mr. Die Grinder, and we're back

in business. It would have been neater to fixture them in the milling

machine, but the grinder works fine and is much faster.

I clayed each piston in turn, until I realized the left/right hand problem and

the BRC piston screwup. A little work with Mr. Die Grinder, and we're back

in business. It would have been neater to fixture them in the milling

machine, but the grinder works fine and is much faster.

Now we've cut the spring seats, ground the sides of the stands to clear the

rockers, and trimmed the guide length. And cleaned, dried, and oiled the

heads for the dozenth time...

Now we've cut the spring seats, ground the sides of the stands to clear the

rockers, and trimmed the guide length. And cleaned, dried, and oiled the

heads for the dozenth time...

After assembling the heads and bolting them down on the gaskets, I found that

the rockers didn't line up with the valve stems, and the center bolt wouldn't

go into its pedestal. The spacers were two different lengths, and the hole in

the shaft was very slightly offset, as were the pedestals. The rocker shafts

had been assembled backwards. Swapping them side for side didn't work, so I

disassembled them, swapped all the bits around, and put them back together.

Everything was fine, then.

After assembling the heads and bolting them down on the gaskets, I found that

the rockers didn't line up with the valve stems, and the center bolt wouldn't

go into its pedestal. The spacers were two different lengths, and the hole in

the shaft was very slightly offset, as were the pedestals. The rocker shafts

had been assembled backwards. Swapping them side for side didn't work, so I

disassembled them, swapped all the bits around, and put them back together.

Everything was fine, then.

Here we are, finally. The two rockers on the right line up correctly, it's

just parallax error from the camera. The pushrods are custom-length Howards

5/16" chrome moly.

Here we are, finally. The two rockers on the right line up correctly, it's

just parallax error from the camera. The pushrods are custom-length Howards

5/16" chrome moly.

Nice color scheme, eh?

While setting the valves, I found two adjustors took a lot more travel than the

others, and both those valves were in coil bind. This was another "put a bag

over it and think about it for a while" thing. I made up a list of things to

check. I kept having visions of eating a $150 pair of head gaskets to fix

something.

While setting the valves, I found two adjustors took a lot more travel than the

others, and both those valves were in coil bind. This was another "put a bag

over it and think about it for a while" thing. I made up a list of things to

check. I kept having visions of eating a $150 pair of head gaskets to fix

something.

Here, I'm verifying that all the valves are the same height.

Next, I checked the lift on each lobe and the height of each spring retainer,

using a solid lifter I moved from hole to hole, and wrote all the results down

on a notepad. All those were correct, too.

Next, I checked the lift on each lobe and the height of each spring retainer,

using a solid lifter I moved from hole to hole, and wrote all the results down

on a notepad. All those were correct, too.

To make a long story short, it turned out to be some bad lifters. The Competition Cams link-bar hydraulic roller lifters have a very long travel - .230"! - and two of them were completely collapsed and wouldn't spring back. Another one was sticky. Bad lifters, okay. Bruce called the vendor he ordered them from, and got them to send some replacements by Federal Express. Meanwhile, I dropped in to talk to John at Motor Pro, a local shop, to see if by any chance he had any lifters like that on hand. He didn't, but he'd seen the problem before. Some roller lifters come packed with a waxy lubricant that gums up and keeps them from working properly. Since the link bars were riveted to the lifter bodies we couldn't get them apart, but soaking them in carburetor cleaner freed them up. Thanks, John!

Now, you might wonder what a collapsed lifter has to do with coil bind. That's due to the peculiarity of the adjustable rockers on shafts - when you run the screw down, it moves the cup down, which changes the rocker motion curve slightly. With the collapsed lifters set to zero lash, we had just enough extra lift to bind the springs.

Yes, it's very strange...

Balancing the pistons. No, the workbench never seems to get much cleaner than

this...

Balancing the pistons. No, the workbench never seems to get much cleaner than

this...

Balancing the rods. You can see the polished shanks good in this picture.

What the heck, it can't hurt, considering 30 pounds of boost...

Balancing the rods. You can see the polished shanks good in this picture.

What the heck, it can't hurt, considering 30 pounds of boost...

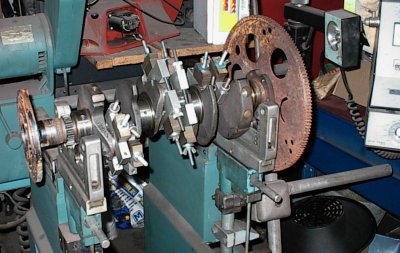

Balancing the crank. The BRCs were a bit heavier than the stock pistons, so

it took a little lead at each end. I'm using the stock 36.6% balance factor.

Balancing the crank. The BRCs were a bit heavier than the stock pistons, so

it took a little lead at each end. I'm using the stock 36.6% balance factor.

Cast steel hydraulic roller cam. I'm hosing off the corrosion inhibitor gunk

with carb cleaner.

Cast steel hydraulic roller cam. I'm hosing off the corrosion inhibitor gunk

with carb cleaner.

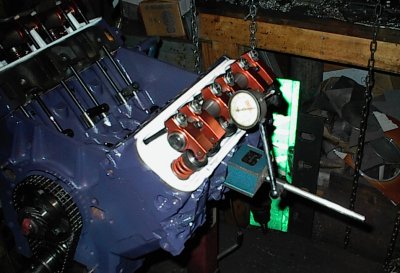

Now we degree the cam. The cam measured 109.5 degrees on a 110 specified

intake lobe center. This is dead nuts in the Real World(tm).

It's not unusual to find cams several degrees off from their stated

centerline.

Now we degree the cam. The cam measured 109.5 degrees on a 110 specified

intake lobe center. This is dead nuts in the Real World(tm).

It's not unusual to find cams several degrees off from their stated

centerline.

The instructions for the Edelbrock timing set didn't say anything about the

cam tensioner. Most roller chain sets for the Buick discard the tensioner, but

I felt there was too much slack in the chain without it.

The instructions for the Edelbrock timing set didn't say anything about the

cam tensioner. Most roller chain sets for the Buick discard the tensioner, but

I felt there was too much slack in the chain without it.

The local GM dealer didn't have a replacement rubbing block in stock, so I

refaced the old one with the belt sander and installed it. Getting that

little spring into the hole in the block is a bugger. A rivet in the back of

the rubbing block keeps the spring from sliding out. It looks very mickey

mouse, but it seems to work okay in practice.

The local GM dealer didn't have a replacement rubbing block in stock, so I

refaced the old one with the belt sander and installed it. Getting that

little spring into the hole in the block is a bugger. A rivet in the back of

the rubbing block keeps the spring from sliding out. It looks very mickey

mouse, but it seems to work okay in practice.

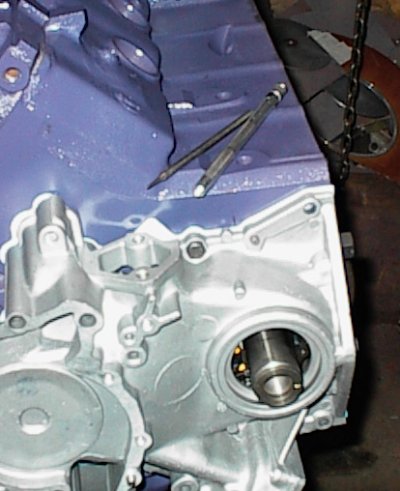

Competition Cams roller thrust button. Slap some clay on the end to check the

timing cover clearance...

Competition Cams roller thrust button. Slap some clay on the end to check the

timing cover clearance...

Install the gasket so everything stacks up right...

Install the gasket so everything stacks up right...

Temporarily install the cover...

Temporarily install the cover...

...and find we have negative clearance, even without any of the shims Comp

provided with the roller bearing kit. I wound up using the belt sander on the

end of the button until I got the clearance right, then hosed it out with

carb cleaner to get the grit out.

...and find we have negative clearance, even without any of the shims Comp

provided with the roller bearing kit. I wound up using the belt sander on the

end of the button until I got the clearance right, then hosed it out with

carb cleaner to get the grit out.

I don't know if the thrust button was overlong to start with, or if it was a

problem with the aftermarket timing cover, or both, but it was no big deal.

Final check. I reached in through the fuel pump port with the dental pick to

make sure the button turned freely. I don't know exactly what the clearance

is, since it's hard to measure less than .010" with clay, but as long as it

turns freely it won't bind against the cover, which is all that matters.

Final check. I reached in through the fuel pump port with the dental pick to

make sure the button turned freely. I don't know exactly what the clearance

is, since it's hard to measure less than .010" with clay, but as long as it

turns freely it won't bind against the cover, which is all that matters.

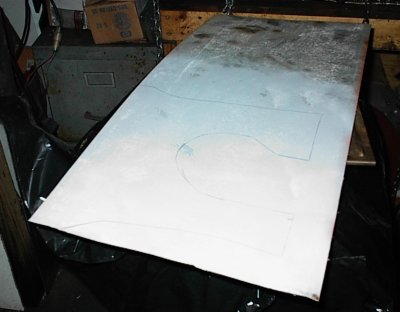

The Grand National engines use a baffled pan. The 4.1 has a different oil pan

bolt pattern, and none of the 4.1s ever had a baffle. I made one out of sheet

metal. Here, I'm making the pattern out of poster board.

The Grand National engines use a baffled pan. The 4.1 has a different oil pan

bolt pattern, and none of the 4.1s ever had a baffle. I made one out of sheet

metal. Here, I'm making the pattern out of poster board.

Now I've laid the poster board pattern onto the sheet metal...

Now I've laid the poster board pattern onto the sheet metal...

...and traced out the lines.

...and traced out the lines.

A little tin snip work is easy.

A little tin snip work is easy.

Baffle welded in place, pan scrubbed with a wire brush to remove MIG spatter,

and first coat of paint. The flanges on the top direct oil slung off the

crank down to the sump. The flanges at the bottom are supposed to catch oil

coming off the other side. The large hole was necessary to clear the pickup

tube; I still have to tilt the pan at an odd angle to get it around the pickup

and down on the block.

Baffle welded in place, pan scrubbed with a wire brush to remove MIG spatter,

and first coat of paint. The flanges on the top direct oil slung off the

crank down to the sump. The flanges at the bottom are supposed to catch oil

coming off the other side. The large hole was necessary to clear the pickup

tube; I still have to tilt the pan at an odd angle to get it around the pickup

and down on the block.

Checking the pickup tube to pan clearance. Perfect. This was the second pan

I tried, by the way. The first one had a much different sump, and the GN

pickup and the sump had major interference. I don't know what kind of car it

was for, but the 4.1s didn't come in very many...

Checking the pickup tube to pan clearance. Perfect. This was the second pan

I tried, by the way. The first one had a much different sump, and the GN

pickup and the sump had major interference. I don't know what kind of car it

was for, but the 4.1s didn't come in very many...

Blue Loctite 242 on the pickup tube bolts. There's a paper gasket between the

tube and the block.

Blue Loctite 242 on the pickup tube bolts. There's a paper gasket between the

tube and the block.

Bruce had found out that the turbo six responded well to increased intake

manifold volume. We figured that we could close off the underside of the

stock intake, which has a small plenum up on stiltlike runners.

Bruce had found out that the turbo six responded well to increased intake

manifold volume. We figured that we could close off the underside of the

stock intake, which has a small plenum up on stiltlike runners.

I cut little pieces of .125" aluminum to block off the cracks. Here, I'm just

getting started. My MIG welder didn't penetrate worth a flip, so I shipped

the intake and the rest of the blockoff bits to Bruce, who took it to someone

with a TIG welder to have it finished up. That guy said it was a pain to

weld, so I didn't feel so bad. Sometimes some aluminum alloys aren't real

compatible to the welding process.

I cut little pieces of .125" aluminum to block off the cracks. Here, I'm just

getting started. My MIG welder didn't penetrate worth a flip, so I shipped

the intake and the rest of the blockoff bits to Bruce, who took it to someone

with a TIG welder to have it finished up. That guy said it was a pain to

weld, so I didn't feel so bad. Sometimes some aluminum alloys aren't real

compatible to the welding process.

Here we go. It's been eight or nine months since I first started, seven

months since the block was honed, ten minutes since I got started on the final

assembly. Step 1: put it on an engine stand.

Here we go. It's been eight or nine months since I first started, seven

months since the block was honed, ten minutes since I got started on the final

assembly. Step 1: put it on an engine stand.

Now we will scrape the decks clean, then carefully sandpaper as necessary,

while being careful not to create low spots. Every major gasket maker goes

into hysterics if you use Scotchbrite cookies on power tools; they are

aggressive enough to cause low spots that will cause sealing problems.

Now we will scrape the decks clean, then carefully sandpaper as necessary,

while being careful not to create low spots. Every major gasket maker goes

into hysterics if you use Scotchbrite cookies on power tools; they are

aggressive enough to cause low spots that will cause sealing problems.

This engine had been rebuilt before, and they apparently got a little wild

with something rotary. One corner had some fairly deep scratches. Not enough

to justify decking the block, but enough to be annoying. The scratches are in

the left corner, obscured by the flash. Well, I guess they weren't

that bad if the camera didn't pick them up.

This engine had been rebuilt before, and they apparently got a little wild

with something rotary. One corner had some fairly deep scratches. Not enough

to justify decking the block, but enough to be annoying. The scratches are in

the left corner, obscured by the flash. Well, I guess they weren't

that bad if the camera didn't pick them up.

Zipping along past many hours of cleaning and painting...

Zipping along past many hours of cleaning and painting...

Balanced, polished, cleaned crank, at home with new main bearings, caps

installed. Now for the new ARP main studs...

Studs installed. For some reason, some of them were longer than others.

The catalog and instructions said nothing; perhaps the Stage I blocks took

different lengths. I've come to find out almost all the stuff for a Buick

assumes Stage parts instead of stock stuff. I put the short studs at the ends

so they wouldn't interfere with the oil pan.

Studs installed. For some reason, some of them were longer than others.

The catalog and instructions said nothing; perhaps the Stage I blocks took

different lengths. I've come to find out almost all the stuff for a Buick

assumes Stage parts instead of stock stuff. I put the short studs at the ends

so they wouldn't interfere with the oil pan.

Ring squaring tool for gapping the rings...

Ring squaring tool for gapping the rings...

You can see the 1/4 NPT tapped hole I added in the water jacket for a drain

plug. Buick didn't provide any, for some reason. This side's plug is well

forward so you can get to it with the starter in place.

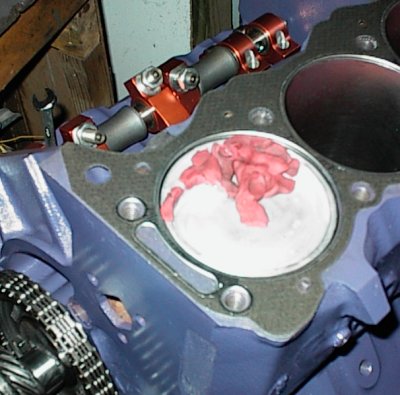

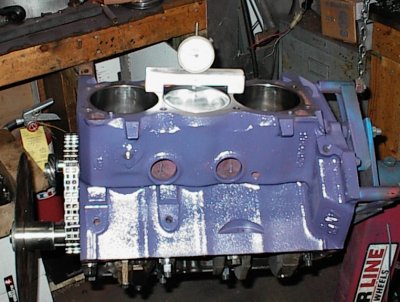

Voila! All the pistons are in, and now we're checking the stack height in

each hole.

Voila! All the pistons are in, and now we're checking the stack height in

each hole.

Just an "in process" shot of the bench. As usual, a glass of iced tea and at

least one notepad for keeping track of all the details.

Just an "in process" shot of the bench. As usual, a glass of iced tea and at

least one notepad for keeping track of all the details.

Cometic three-layer metal head gaskets. They're supposed to be the bling-

bling for high boost turbo engines.

Cometic three-layer metal head gaskets. They're supposed to be the bling-

bling for high boost turbo engines.

These critters cost $150 per pair.

The three layers are riveted together with tabs outside the clamping area.

The three layers are riveted together with tabs outside the clamping area.

The Stage II engines had six bolts per cylinder, so there are extra bolt holes

we won't be using. The gaskets had embossed areas that looked like they might

be intended to seal various water holes, but they didn't line up with anything

in particular. It didn't look like they would hurt anything, though. Perhaps

more Stage stuff.

The Stage II engines had six bolts per cylinder, so there are extra bolt holes

we won't be using. The gaskets had embossed areas that looked like they might

be intended to seal various water holes, but they didn't line up with anything

in particular. It didn't look like they would hurt anything, though. Perhaps

more Stage stuff.

The gaskets had a very thin plastic coating. I wasn't particularly confident

they would properly seal the coolant passages, so I sprayed them with KW

Kopper-Kote gasket sealer.

The gaskets had a very thin plastic coating. I wasn't particularly confident

they would properly seal the coolant passages, so I sprayed them with KW

Kopper-Kote gasket sealer.

Note the reflections from the cylinder walls; moly rings require a very smooth

finish, unlike the cross-hatch you needed with old-style chrome rings.

Lots of flash flare in this shot; just showing Teflon sealer applied to the

ARP head stud. If you don't use sealer there's a chance water can seep up

around the threads and get into the oil. And when you clean the threads with

a tap like ARP recommends, that chance approaches certainty.

Lots of flash flare in this shot; just showing Teflon sealer applied to the

ARP head stud. If you don't use sealer there's a chance water can seep up

around the threads and get into the oil. And when you clean the threads with

a tap like ARP recommends, that chance approaches certainty.

Much-modified heads sitting down on their expensive head gaskets. Finally it

becomes a long block!

Much-modified heads sitting down on their expensive head gaskets. Finally it

becomes a long block!

Spare pair of stock valve covers keeps overspray off the white paint on the

heads. And the Z-28 springs, and the titanium retainers, and... the spray

can says "Dupli-Color Plum Purple." Bruce wanted black. I told him it was

just a sort of purplish shade of black...

Spare pair of stock valve covers keeps overspray off the white paint on the

heads. And the Z-28 springs, and the titanium retainers, and... the spray

can says "Dupli-Color Plum Purple." Bruce wanted black. I told him it was

just a sort of purplish shade of black...

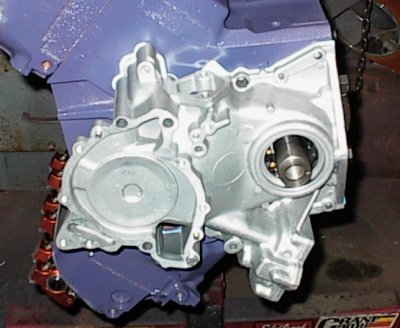

The aftermarket timing cover has a deep pocket for the oil pump gears, to take

longer, high volume gears. It also came drilled for both the early and late

Buick oil pan bolt patterns.

The aftermarket timing cover has a deep pocket for the oil pump gears, to take

longer, high volume gears. It also came drilled for both the early and late

Buick oil pan bolt patterns.

The cover also came with a rubber seal, which I've just installed, and a whole

assortment of springs to set the oil pressure. Not a bad part!

The cover also came with a rubber seal, which I've just installed, and a whole

assortment of springs to set the oil pressure. Not a bad part!

Ta-daa! A simple wooden carrier to keep it from rolling around in the back of

Bruce's truck, plastic to keep the grunge out.

Ta-daa! A simple wooden carrier to keep it from rolling around in the back of

Bruce's truck, plastic to keep the grunge out.

M A X I M U M O V E R D R I V E R A C I N G E N G I N E S

4.1 Buick V6 for Bruce Plecan, Arcanum OH

completed 12/03/03 (long block)

4.00 bore

3.40 stroke

256 CID, 4202cc (4.2L)

700 4.0 x 3.4

8.24 stock 4.1 composition gasket

48 stock chamber size

35 piston dish volume

------

791.24 cc total volume

8.24 stock 4.1 composition gasket

48 chamber size

35 dish volume

------

91.24 cc clearance volume

791.24 / 91.24 = 8.67:1 CR

warranty: if it breaks, you get to keep all the pieces you can find

COMPONENTS ---------------------------------------------------------------

Block:

4.1 block

4.000 bore

new cam bearings (had to scape #1 for clearance), Dura-Bond F-30

drilled and tapped for water drains

installed 1/8 NPT bushing for cylinder pressure measurement

chased all threaded holes

Rust-Oleum red primer, Dupli-Color Plum Purple engine paint

ARP main studs

rubber rear main seal

rubber front seal

ARP head studs, ARP and Mr. Gasket washers (studs too long)

studs set in Teflon sealer

mains STD uppers, .001 lowers, King MB-443-AM

Oiling:

4.1 oil pan

new 4.1 pickup tube

drilled oil passages larger

custom tray/scraper/baffle welded into pan

large neodymium magnet in pan by drain plug

new timing cover with built-in HV pump, PN 6571HI

offset #2,3,4 cam bearings, new .090 oil holes

Crankshaft:

stock 4.1 crank, undercut fillets

not turned; polished journals

balanced with 4.1 damper, flexplate

main journals:

#1 2.4990"

#2 2.4987"

#3 2.4987"

#4 2.4987"

Connecting Rods:

stock rods

polished shanks

ARP 7/16" rod bolts, 123-6002, 1.7" U.H.L.

balanced

bronze bushed for Chevy pins

single .125 oil hole at top of pin end

standard size bearings, King CR-6616-AM

Pistons:

BRC custom forgings

35cc round dish

5/32, 5/32, 7/32 standard Chevy ring width

CBC-2 ceramic thermal barrier coated tops

TLML moly antifriction coated sides

dual Spirolox pin retention

pin oiling via drilled passages to oil rings

2.5" taper wall pins .927" dia.

pistons are 6 LH exhaust instead of 4 LH, 2 RH; Stage II valve

positions

hand-cut valve notches to clear std. exhaust valves, .080+"

~.200 valve vertical clearance, all valves

Stack Height:

#1) -.024" #2) -.021"

#3) -.022" #4) -.025"

#5) -.025" #6) -.027"

Rings:

Hastings moly rings, 4.000 nominal bore, 5/32, 5/32, 7/32

#1 .020" #2 .022"

.015" .016"

.022/.022" .027/.027"

#3 .020" #4 .020"

.017" .016"

.023/.023" .023/.023"

#5 .020" .020"

.016" .014"

.025/.023" .023/.023"

Cylinder Heads:

#445 casting cylinder heads

48cc chambers (stock)

coated chambers, exhaust ports, valves CBC-2 thermal barrier

stock integral iron valve guides (OK)

blocked heat passages in heads with steel dowels, welded and pinned

decked flat

all threaded holes chased

recut guides to .640 intake, .790 exhaust, for retainer/seal clrc.

nylon unbrellas on intake valves

Olds hard nylon umbrella seals on intake side, .110 thick, .090" lift

clearance

no seals on exhaust side, .090" lift clearance

Chevy steel umbrellas

Mobil 1 grease around keepers for oil control

narrowed pedestals to clear roller rocker bodies

springs installed at 1.71 nominal; cut seats down for spring height

standard valve keepers

Chevy Z-28 valve springs, Competition Products, good to .510 lift

Chevy titanium retainers, 1.25" diameter

.070" intake seats

.090" exhaust seats

spring and lift measurements, on assembled long block:

cyl. vlv. closed open v.lift spring (between coils)

#1 E 1.82 1.32 .500 .028

I 1.81 1.31 .500 .028

#3 I 1.82 1.31 .510 .030

E 1.80 1.29 .510 .030

#5 I 1.81 1.30 .510 .018 (crooked coils)

E 1.80 1.305 .495 .026

#2 E 1.76 1.26 .500 .028

I 1.77 1.27 .500 .030

#4 I 1.81 1.31 .500 .030

E 1.81 1.31 .500 .030

#6 I 1.80 1.30 .500 .018 (crooked coils)

E 1.81 1.31 .500 .030

Cam Specification:

Comp Cams BV69 258 HR 10 grind

Serial No UE7146

Intake Ex

Valve Adj Hyd Hyd

Gross Lift .496 .496

Dur@ 006 258 258

Valve Timing Open Close

at .050 In 7- BTDC 33 ABDC

Ex 33 BBDC 7- ATDC

at 110 degrees intake center line

Dur at .050 In, 206 Ex, 206

Lobe lifts .320

Lobe separation 110 degrees

Valvetrain:

cast hydraulic roller cam

Comp Cams Chevrolet hydraulic roller lifters, link bar type

.230 lifter travel

preloaded 3/4 turn

Edelbrock roller timing chain

stock cam chain tensioner

cam degreed in at 109.5

Comp Cams roller thrust button, PN 269, ~.005" clearance

drill .090" holes in #2, 3, 4 cam bearings, index to restrict oil flow

left #1 cam bearing alone

had to scrape front cam bearing for cam to turn

5/16" pushrods, length 8.25"; Howards Cams customs, PN PO209503

T&D shaft mount roller rockers, 1.6:1

Torque:

ARP main studs, 7/16", with ARP moly lube: 70 ft-lb

ARP rod bolts, 123-6002, with ARP moly lube: 50 ft-lb

ARP head studs, 1/2", with ARP moly lube: 90 ft-lb

Miscellaneous:

turning torque 15-20 ft-lb, cam but no valvetrain

new water pump

head studs too long; 4 studs 1/2" too long, used 4 bolts on

passenger outboard

used Mr. Gasket washers stacked on ARP washers

Cometic multi layer metal head gaskets, H1603SP1045QS. .045 thick

used KW Copper-Kote on gaskets